Penis Rotor

GT Godfather!

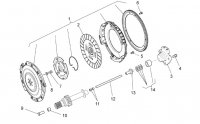

The factory released a service bulletin a few months back about the thrust bearing on some 8V's most notably early Stelvios and Grisos becomming noisy in service. While no further explanation was really given it was obvious that the bearings were failing in some cases and the sollution was said to be to replace the whole thrust assembley with a new one with two bearings that has a superceeded part number to the original.

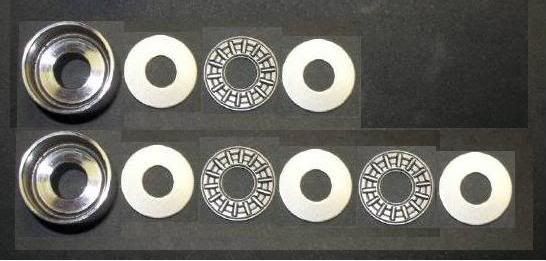

Now MarkIII who posts here was having some problems with his clutch on his 8VG, we found out last week that they were in fact unconnected with the thrust issue but since it was something that had been mentioned by the factory I went ahead and ordered the new part that comes as a complete assembly, supposedly a new thrust cup and two bearings. Well, they weren't in stock so they went on BO and duly arrived a couple of week later. Unfortunately they only has ONE bearing in the kit!!!! :roll:

Last week when we pulled the swingarm on Mark's bike to get at the slave cylinder and thrust mechanism we found no problem with his thrust mechanism but in for a penny? In for a pound! We used the original bearing and the new one as shown on the service bulletin. His clutch pushrod length was correct but interestingly, even though adding another bearing effectively increases the length of the thrust mechanism by 4mm there is no suggestion that anything else in the system needs altering.

This is by the by, the whole thing went back together fine and we then found the source of the problem that Mark said he'd probably post about but I'd also bought a second thrust assembley to put in stock and today did a bit of measuring only to find that the actual thrust cup is identical to the 'Old' one, hence the extra length in the mechanism which means that rather than buying the $80 assembley from Guzzi all one actually NEEDS to do if you want to add another bearing is go to the bearing factor and purchase a 10 x 24 x 4 Torrington and while I have yet to purchase one it'll sure as shit be cheaper than $80 :mrgreen:

Pete

Now MarkIII who posts here was having some problems with his clutch on his 8VG, we found out last week that they were in fact unconnected with the thrust issue but since it was something that had been mentioned by the factory I went ahead and ordered the new part that comes as a complete assembly, supposedly a new thrust cup and two bearings. Well, they weren't in stock so they went on BO and duly arrived a couple of week later. Unfortunately they only has ONE bearing in the kit!!!! :roll:

Last week when we pulled the swingarm on Mark's bike to get at the slave cylinder and thrust mechanism we found no problem with his thrust mechanism but in for a penny? In for a pound! We used the original bearing and the new one as shown on the service bulletin. His clutch pushrod length was correct but interestingly, even though adding another bearing effectively increases the length of the thrust mechanism by 4mm there is no suggestion that anything else in the system needs altering.

This is by the by, the whole thing went back together fine and we then found the source of the problem that Mark said he'd probably post about but I'd also bought a second thrust assembley to put in stock and today did a bit of measuring only to find that the actual thrust cup is identical to the 'Old' one, hence the extra length in the mechanism which means that rather than buying the $80 assembley from Guzzi all one actually NEEDS to do if you want to add another bearing is go to the bearing factor and purchase a 10 x 24 x 4 Torrington and while I have yet to purchase one it'll sure as shit be cheaper than $80 :mrgreen:

Pete