OldJock

Cruisin' Guzzisti

Got another question

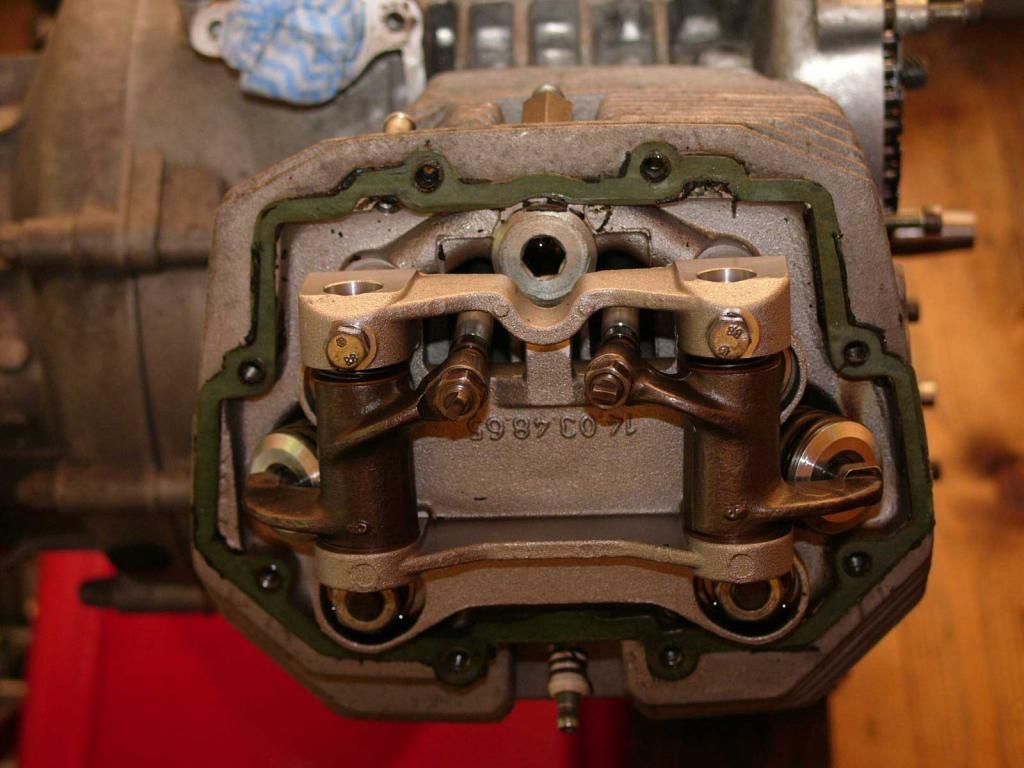

I was doing the tappets on the LM 1000 and I'm running out of tappet adjustment.

I know that valve recession is a culprit but the heads were rebuilt a few years back and have been like this since, so I'm wondering if they are set to the correct stack height.

There is no mention of height in the supplement for the LM 1000 so I assumed (always dangerous) that it would therefore be the same as the measurements for the G5, 35.7 to 36mm from the head to the underside of the retaining collet.

Checking old photos before the refurb they appear to have quite a bit more free thread on the adjuster, so I was wondering if that figure is correct.

Going off to try to check what the actual height is but unsure if I'll be able to get a decent reading with the heads is situ

John

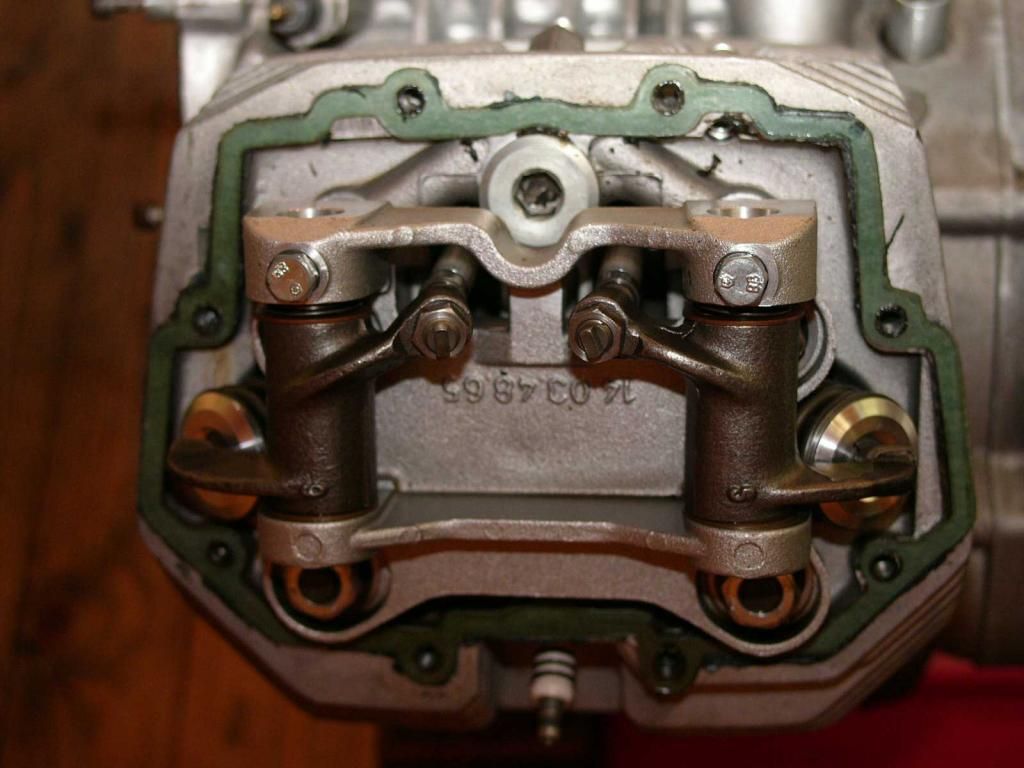

I was doing the tappets on the LM 1000 and I'm running out of tappet adjustment.

I know that valve recession is a culprit but the heads were rebuilt a few years back and have been like this since, so I'm wondering if they are set to the correct stack height.

There is no mention of height in the supplement for the LM 1000 so I assumed (always dangerous) that it would therefore be the same as the measurements for the G5, 35.7 to 36mm from the head to the underside of the retaining collet.

Checking old photos before the refurb they appear to have quite a bit more free thread on the adjuster, so I was wondering if that figure is correct.

Going off to try to check what the actual height is but unsure if I'll be able to get a decent reading with the heads is situ

John