leafman60

Cruisin' Guzzisti

This issue is given virtually no attention in the Guzzi owners manual or shop manual. Installing the axle and tightening the pinch bolts is the most critical part of the process. It's easy, once you've done it.

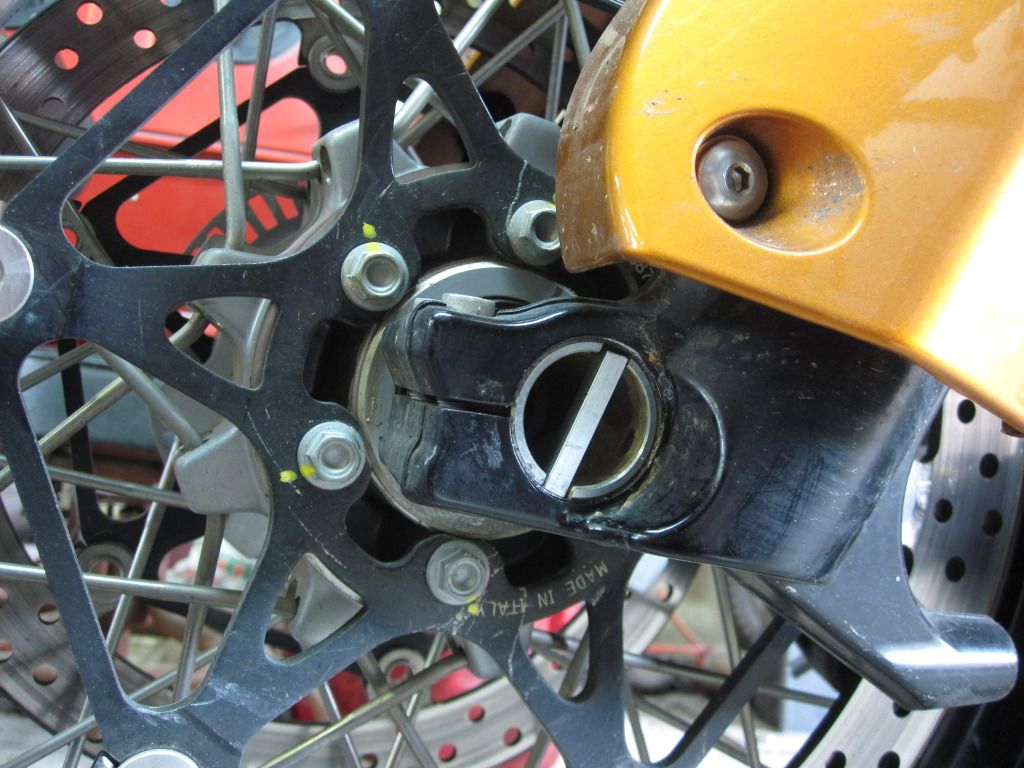

The 2012 NTX has a redesigned fork leg axle pinch clamp to minimize past problems of broken axle clamps.

Wheel removal -

1. Place bike on center stand and place support block under engine to prevent the bike from inadvertently falling forward without the front wheel.

2. Remove the two 13 mm mount bolts attaching each brake caliper and let them hang out of way.

3. Loosen and remove 30 mm front axle nut and then loosen socket head axle pinch bolts.

4. Using a wood mallet or soft drift, tap threaded end of axle into the right fork leg to reveal pulling holes on non-threaded end of axle. With screwdriver or suitable pin inserted into hole(s), pull axle out while supporting wheel.

Alternatively, you can drift the axle out far enough to simply grab the non-threaded end with one hand while holding top of wheel with the other and yank the axle out.

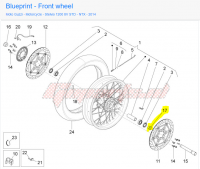

5. Remove wheel and note the removable spacer on rider’s right side of wheel at the bearing.

Wheel installation –

1. Prepare assembly parts. Remove and clean rider's right side axle spacer and lightly grease seal lip. Insert right side spacer with flange position out from wheel. Blow any loose dirt or debris from pinch bolts and clamps. Wipe bore of fork axle holes clean. Clean and lightly grease axle.

2. Carefully position wheel between forks and line-up axle holes.

3. While supporting wheel from beneath or holding with one hand, insert axle into rider’s left fork and through the wheel. Line up right side hole and push axle on through using hand pressure or wood mallet.

4. Tighten 30 mm big axle nut hand-tight with a wrench until the axle spins in fork holes. This will pull the axle and wheel up against the spacer on the rider's right side of the axle. Run down all four pinch bolts only finger tight. Don’t tighten pinch bolts yet.

5. Inspect brake pads and install brake calipers and torque bolts to 50NM.

6. Remove support under engine and carefully push bike off center stand. Compress forks by bouncing a time or two to make sure fork legs align on axle. Visually inspect brake rotor alignment in calipers.

7. Leave bike off center stand and tighten rider’s left fork pinch bolts in alternating steps to 10 NM. This keeps axle from turning while tightening axle nut. Don’t tighten riders right pinch bolts yet.

An alternative to hold axle from turning is to cut a short piece of key stock or use something similar to insert into the end notches of the non-threaded end of the axle.

8. Tighten big 30 mm axle nut to 80 NM. Loosen the rider's left pinch bolts again if you did not use the key stock method of holding the axle, bounce the forks one more time and then tighten all four pinch bolts in alternating steps to 10 NM.

9. Pump-up brake calipers with brake lever.

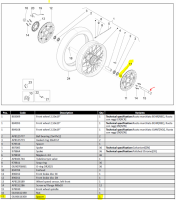

Torque settings front wheel:

Brake caliper mounts 13 mm head size, 50 NM

Big axle nut 30 mm head size, 80 NM

Pinch bolts socket head, 10 NM

10 NM = 88.5 inch pounds = 7.376 foot pounds

The 2012 NTX has a redesigned fork leg axle pinch clamp to minimize past problems of broken axle clamps.

Wheel removal -

1. Place bike on center stand and place support block under engine to prevent the bike from inadvertently falling forward without the front wheel.

2. Remove the two 13 mm mount bolts attaching each brake caliper and let them hang out of way.

3. Loosen and remove 30 mm front axle nut and then loosen socket head axle pinch bolts.

4. Using a wood mallet or soft drift, tap threaded end of axle into the right fork leg to reveal pulling holes on non-threaded end of axle. With screwdriver or suitable pin inserted into hole(s), pull axle out while supporting wheel.

Alternatively, you can drift the axle out far enough to simply grab the non-threaded end with one hand while holding top of wheel with the other and yank the axle out.

5. Remove wheel and note the removable spacer on rider’s right side of wheel at the bearing.

Wheel installation –

1. Prepare assembly parts. Remove and clean rider's right side axle spacer and lightly grease seal lip. Insert right side spacer with flange position out from wheel. Blow any loose dirt or debris from pinch bolts and clamps. Wipe bore of fork axle holes clean. Clean and lightly grease axle.

2. Carefully position wheel between forks and line-up axle holes.

3. While supporting wheel from beneath or holding with one hand, insert axle into rider’s left fork and through the wheel. Line up right side hole and push axle on through using hand pressure or wood mallet.

4. Tighten 30 mm big axle nut hand-tight with a wrench until the axle spins in fork holes. This will pull the axle and wheel up against the spacer on the rider's right side of the axle. Run down all four pinch bolts only finger tight. Don’t tighten pinch bolts yet.

5. Inspect brake pads and install brake calipers and torque bolts to 50NM.

6. Remove support under engine and carefully push bike off center stand. Compress forks by bouncing a time or two to make sure fork legs align on axle. Visually inspect brake rotor alignment in calipers.

7. Leave bike off center stand and tighten rider’s left fork pinch bolts in alternating steps to 10 NM. This keeps axle from turning while tightening axle nut. Don’t tighten riders right pinch bolts yet.

An alternative to hold axle from turning is to cut a short piece of key stock or use something similar to insert into the end notches of the non-threaded end of the axle.

8. Tighten big 30 mm axle nut to 80 NM. Loosen the rider's left pinch bolts again if you did not use the key stock method of holding the axle, bounce the forks one more time and then tighten all four pinch bolts in alternating steps to 10 NM.

9. Pump-up brake calipers with brake lever.

Torque settings front wheel:

Brake caliper mounts 13 mm head size, 50 NM

Big axle nut 30 mm head size, 80 NM

Pinch bolts socket head, 10 NM

10 NM = 88.5 inch pounds = 7.376 foot pounds