Mike.C said:Mate of mine uses THIS TANK FOAM HERE in his enduro race bikes, might be worth a try.

Great project Ray.

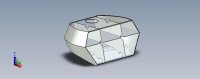

Yep, we're looking at that evomx foam. They claim it doesn't break down due to gas additives, and is good for 15 years. But that comes at a price of @ $100 for 6 gal. We may just put a baffle or two in the tank design instead.....not sure yet. Or try and find some military grade reticulated polyurethane foam on our own at a better price.