LOL sometimes I scare myself too.  Your advice is very sound and reasonable but I was too eager to finish the work unfortunately. If I waited for a day all would be just fine. Anyway, I'll leave the "fix" the way it is - at least until I absolutely need to open it, since I've already driven a bike for a couple of days and I think I'd do more damage than good by trying to unscrew it now. I can't imagine a scenario where I'd have to open that hole again, what do you think?

Your advice is very sound and reasonable but I was too eager to finish the work unfortunately. If I waited for a day all would be just fine. Anyway, I'll leave the "fix" the way it is - at least until I absolutely need to open it, since I've already driven a bike for a couple of days and I think I'd do more damage than good by trying to unscrew it now. I can't imagine a scenario where I'd have to open that hole again, what do you think?

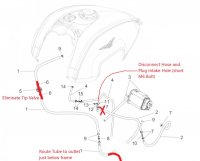

Every single modification I made did alter the air/exhaust flow but the bike was running quite badly before that already. My greatest suspicion is the tip valve which didn't look dirty but the flow was very low. After the mods it's running with much more power all throughout the rpm range, and is running COOLER! I've no idea what happened but I like it when I ride. Also, no more moaning, no more loping at the stops, no more hanging throttle.

I've no idea what happened but I like it when I ride. Also, no more moaning, no more loping at the stops, no more hanging throttle.

Todd's package should come in a week or two so there shouldn't be too much harm to the engine before I get the fueling perfected. And then it shall be glorious!

Every single modification I made did alter the air/exhaust flow but the bike was running quite badly before that already. My greatest suspicion is the tip valve which didn't look dirty but the flow was very low. After the mods it's running with much more power all throughout the rpm range, and is running COOLER!

Todd's package should come in a week or two so there shouldn't be too much harm to the engine before I get the fueling perfected. And then it shall be glorious!

Wroom, you're scaring me man, the link you provided for the "Stik'n Seal" makes the frightening statements: 1) ADHESIVE, 2) Not for metal-to-metal applications. I'm hoping you haven't ridden that bike very far and I would try to remove it if that were my bike. It might be nothing but honestly, you used the wrong product. If we are talking about using this product on the bolt in the throttle body, keep in mind that the inside of the throttle body is under negative pressure most of the time. I would not like to think of any of that stuff getting sucked into the engine, it will hit very hot valves/valve seats on the way in and MUCH hotter valves/valve seats on the way out. I would suggest not using anything, just the proper torque on the bolt.

As for the various modifications you've made to your bike, every one of them has altered the induction metrics. Most leading to increased flow. The default fuel maps will be way wrong under the new conditions, in fact you may have been experiencing the effects of putting your bike into "limp home mode". You need dynamic oxygen sensor input and dynamic fuel mixture control in the worst way. Todd's GT-Rx fueling package is a good way to get a closed loop dynamic fuel management modification, you are going in the right direction. Good luck with it; and please post your results on the forum. Todd did make a comment on one of his posts about the GT-Rx fueling package which does apply to the mods you've already made to your bike:

"I need to mention here, that even a bone stock bike really needs the fueling corrected (dealers cannot do this) in order to have a long, healthy life. Any modifications exacerbates the uber-lean fueling." (Todd)

Later my friend.

Den.