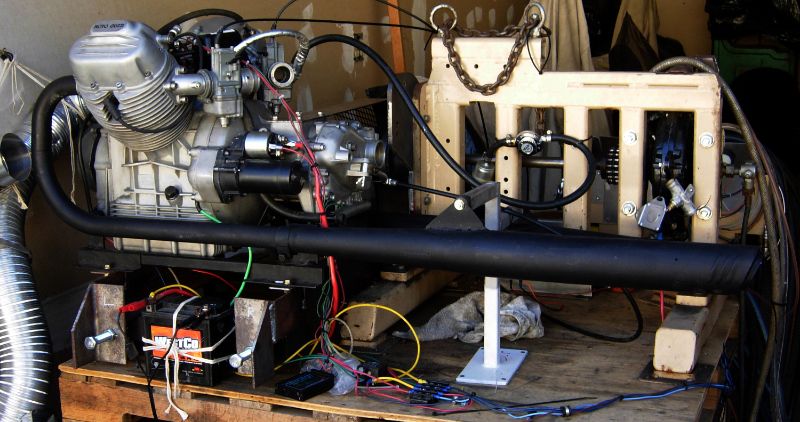

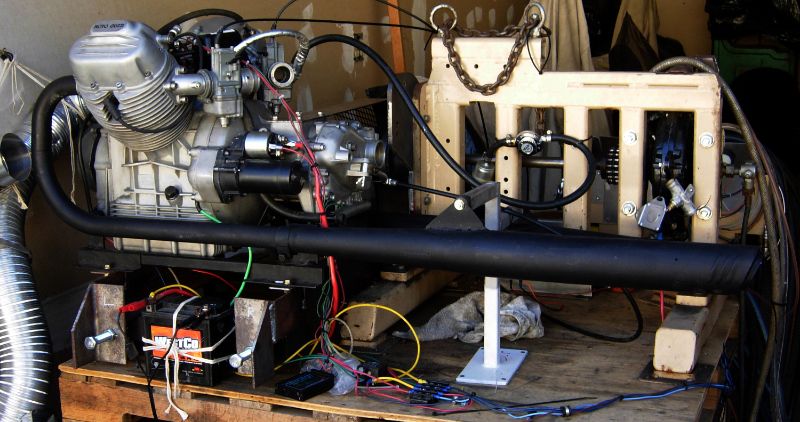

1st run with Mike R. heads (glue and screw) and new megacycle cam.

Kept the RPM down due to noise and I didn't wanna blow this thing up just yet.

75HP @ 5,000 RPM. A good improvement from the previous incarnation.

Kept the RPM down due to noise and I didn't wanna blow this thing up just yet.

75HP @ 5,000 RPM. A good improvement from the previous incarnation.