leafman60

Cruisin' Guzzisti

Problems are associated with the stock sparkplug caps on the Stelvio and other 8V motors.

Commonly-used replacement spark plug caps are NGK SB05E. If found, SD05E should fit tighter around the plug insulator and provide a better weather seal. Likewise, the sealing boot from an SD05F threaded terminal type cap can be installed on the SB05E to provide proper tight fit on the plug.

You do not need to remove any of the side covers of the bike for this operation. I did not need any wires longer than the stock leads and I did not need to re-route the stock leads.

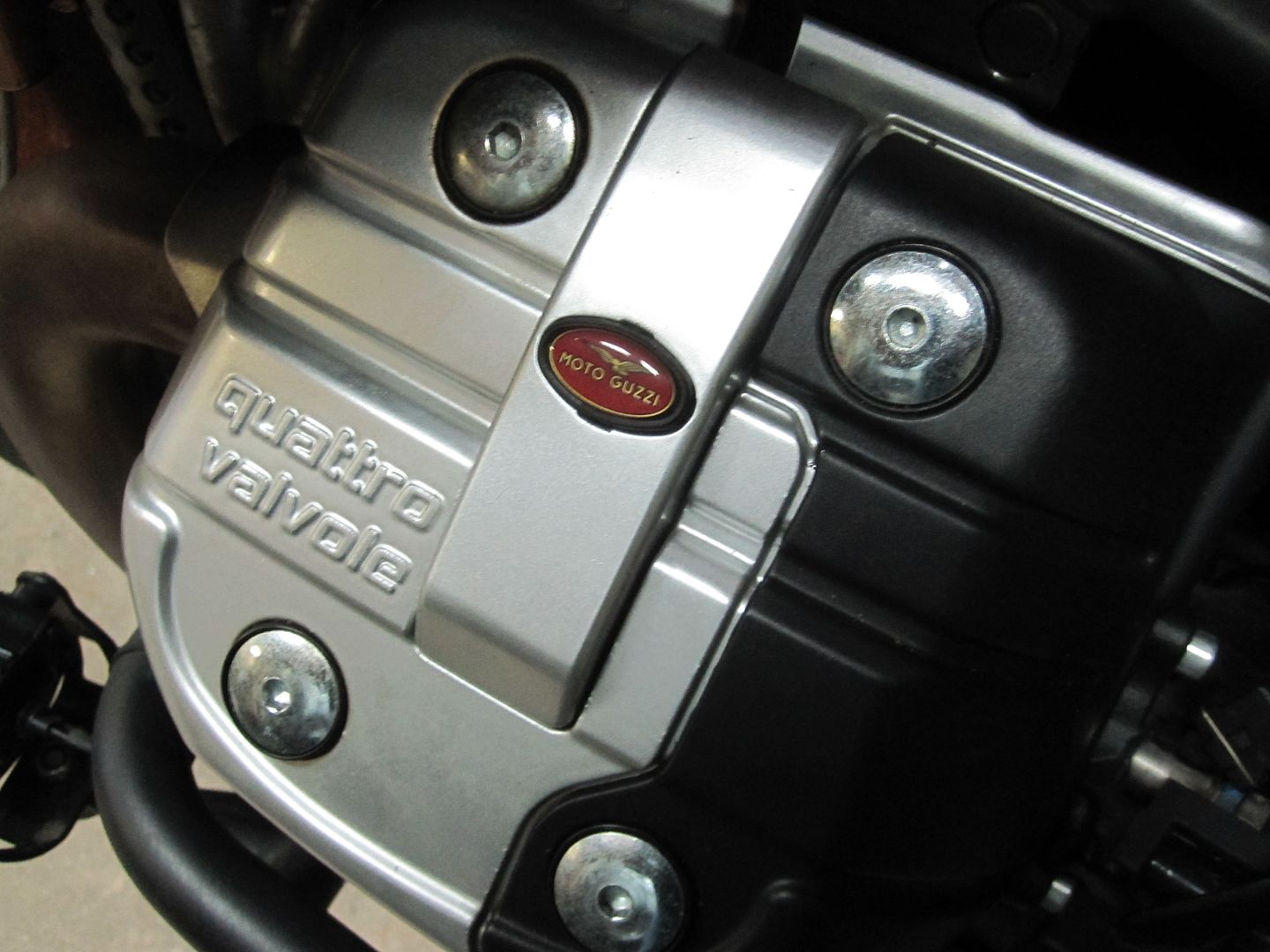

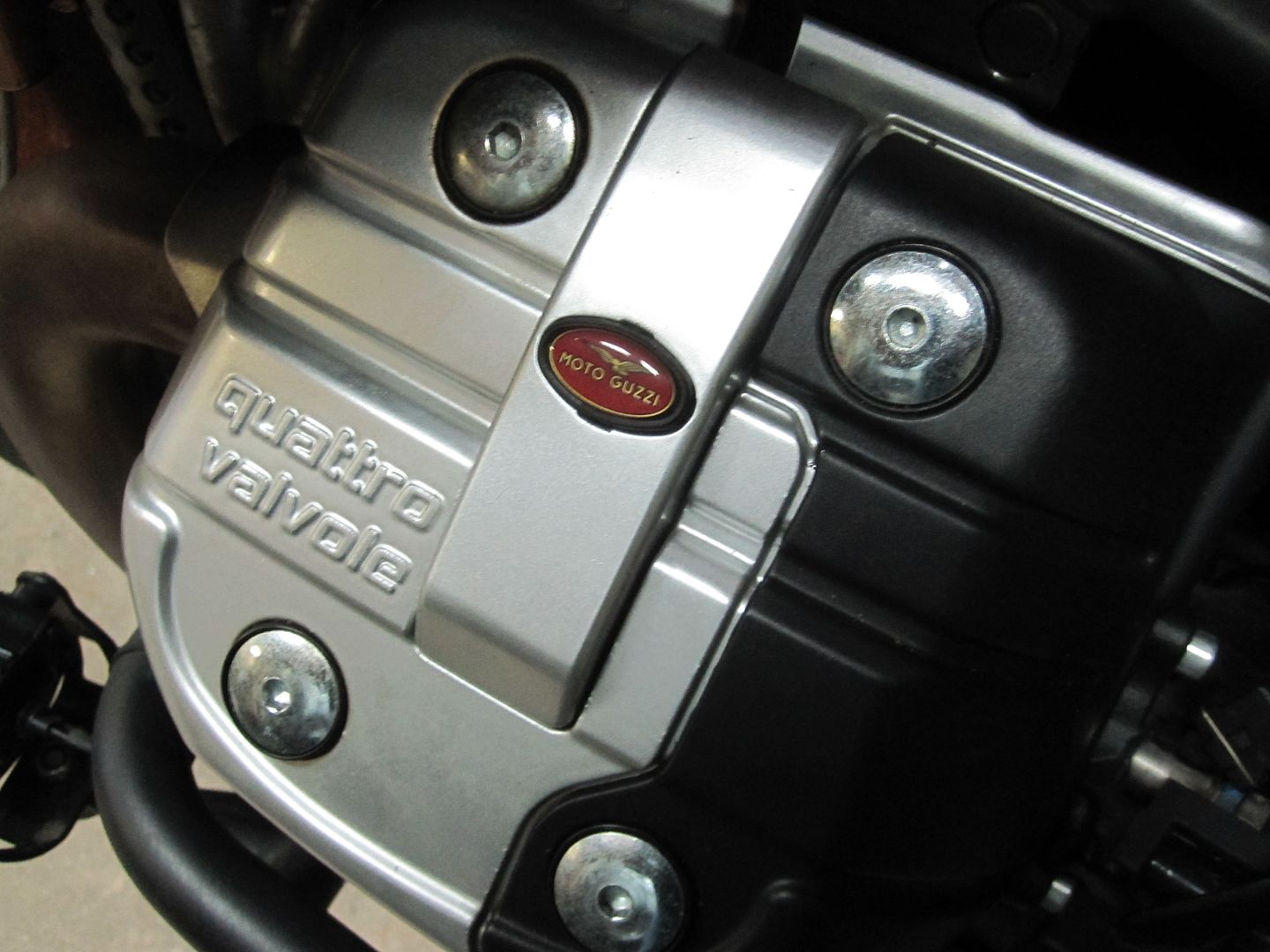

First, remove the snapped-in MG logo badge with a small screwdriver or similar pry.

Remove the screw that holds the silver wire cover.

The stock spark plug boot cap is exposed.

Pull the boot cap off the spark plug. I typically use a nylon tie wrapped around the boot.

It should come off easily. The Guzzi manual says to use a screwdriver inserted through the exhaust port cooling fins to pry up on the bottom of the boot.

If you wish to remove the wire lead from the boot before cutting it, grasp the wire firmly and screw it out from the rubber boot. The brass threads of the wire terminal end is obvious.

Cut the stock wire above the shrink-fit covering of the terminal end.

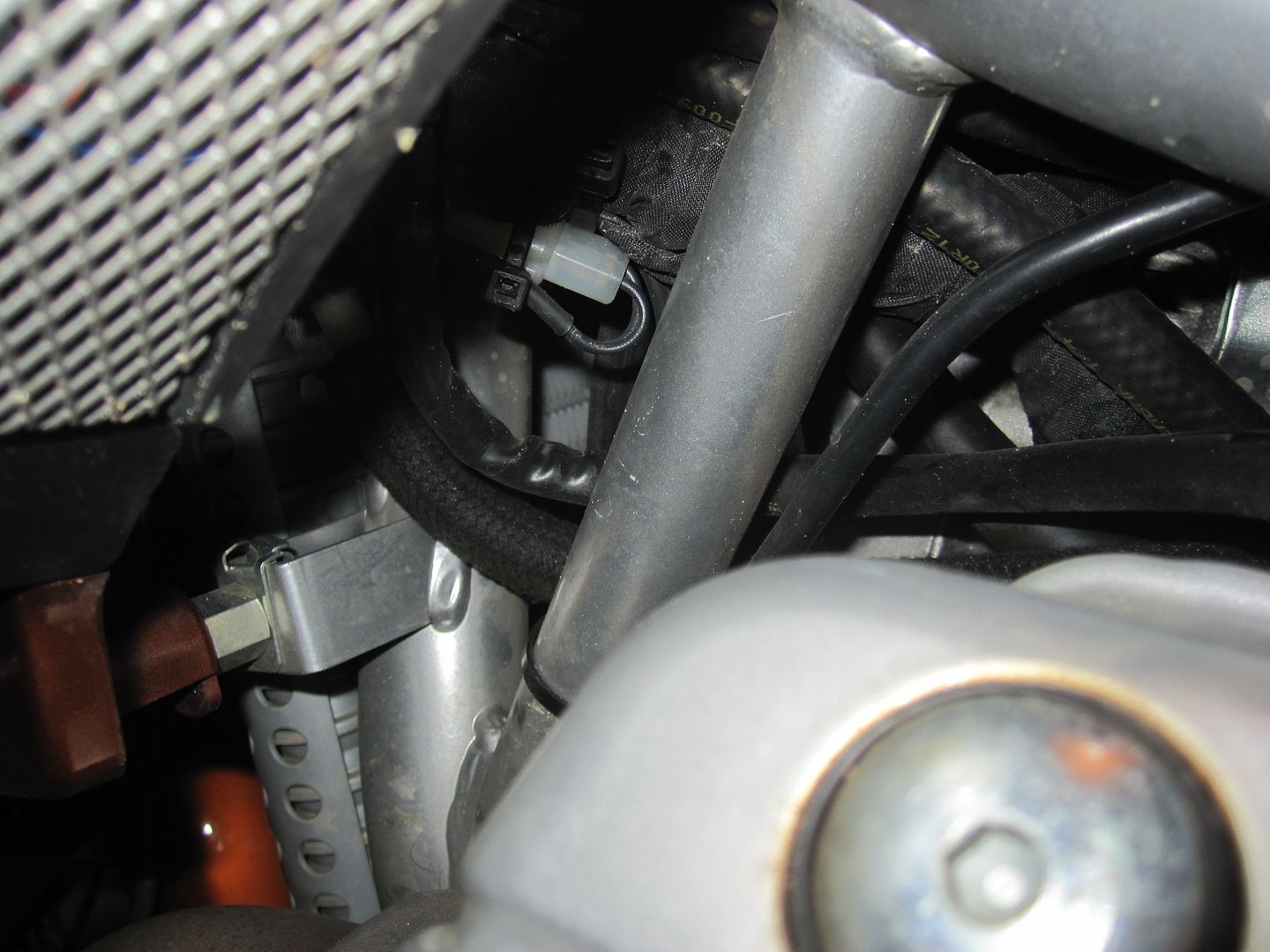

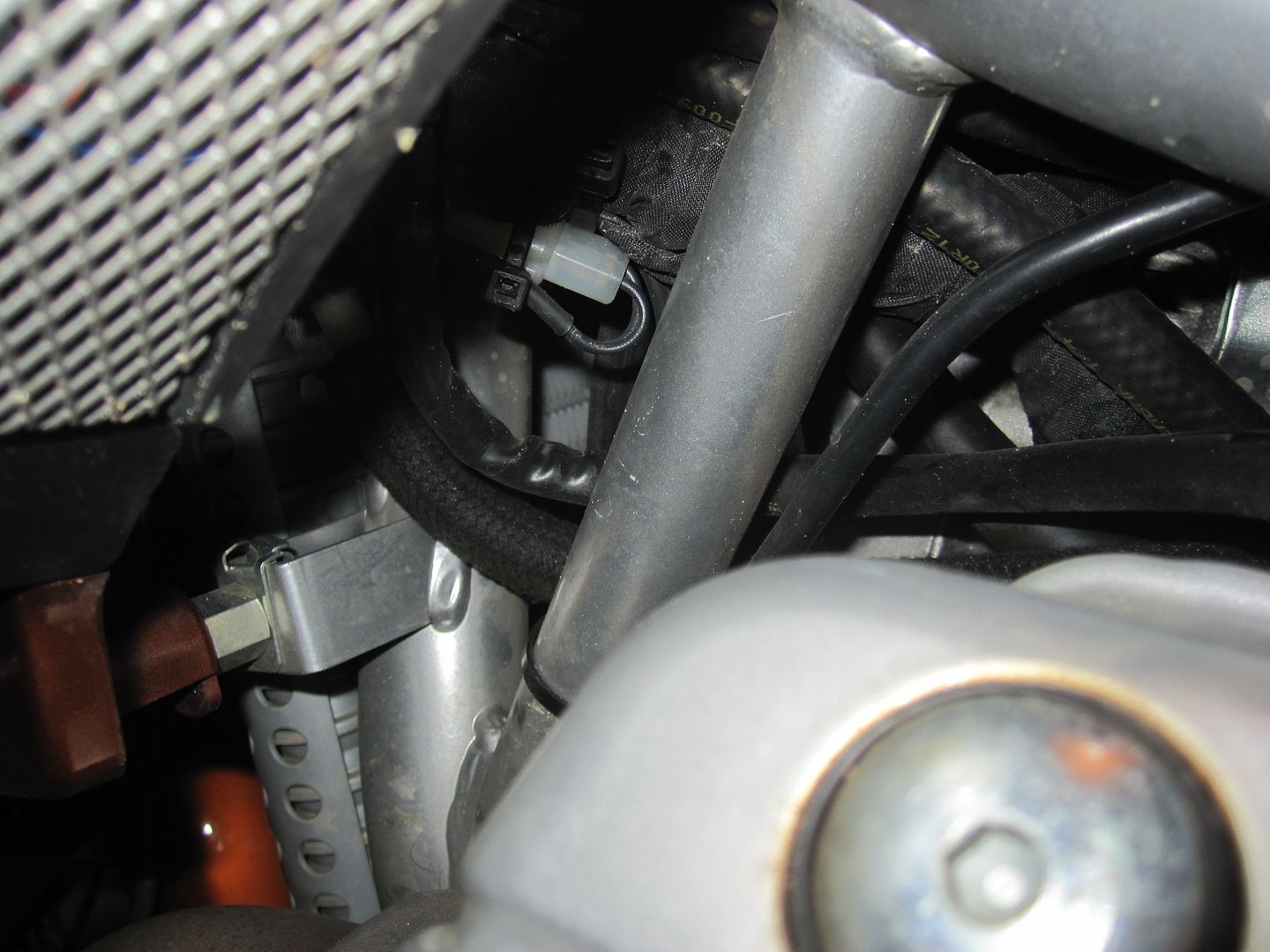

Check the length of the wire to verify that it is long enough to reach to the top of the plug well. My Stelvio had more than enough wire on both left and right cylinder to easily reach the plug well. If the left side is too short, you can re-route the wire around the frame member, shown here near the coil, to gain more slack.

Note that the plug wire is routed inside a protective plastic conduit. While performing this task, I discovered one of my conduits filled with water. To make sure water will drain from the conduit and to give enough wire exposure for fitting the new spark plug cap, cut back the protective conduit about an inch and a half or 35-40 mm.

I suggest removing the weather seal boot from the NGK cap instead of trying to insert the wire through it.

The wire end of the NGK replacement cap showing the male threads that go up into the plug wire end in order to make electrical contact.

Slip the sealing boot onto the plug wire. Then, hold the wire and cap firmly. Insert the wire end into the cap and screw the wire onto the male threads inside the cap. The male threads screw up into the metal wire conductor in the center of the insulated plug wire.

Work the rubber sealing boot onto the plastic plug cap and insert the cap down into the valve cover until it snap snugly onto the spark plug. A small amount of dielectric grease on the plug insulator or the inside of the sealing boot will help.

Fit the wire down into the holding area and install the silver cover with the small screw and reinstall the snap-in MG logo piece. A good idea is to apply some silicone or glue under the logo badge to make sure it does not vibrate out.

Commonly-used replacement spark plug caps are NGK SB05E. If found, SD05E should fit tighter around the plug insulator and provide a better weather seal. Likewise, the sealing boot from an SD05F threaded terminal type cap can be installed on the SB05E to provide proper tight fit on the plug.

You do not need to remove any of the side covers of the bike for this operation. I did not need any wires longer than the stock leads and I did not need to re-route the stock leads.

First, remove the snapped-in MG logo badge with a small screwdriver or similar pry.

Remove the screw that holds the silver wire cover.

The stock spark plug boot cap is exposed.

Pull the boot cap off the spark plug. I typically use a nylon tie wrapped around the boot.

It should come off easily. The Guzzi manual says to use a screwdriver inserted through the exhaust port cooling fins to pry up on the bottom of the boot.

If you wish to remove the wire lead from the boot before cutting it, grasp the wire firmly and screw it out from the rubber boot. The brass threads of the wire terminal end is obvious.

Cut the stock wire above the shrink-fit covering of the terminal end.

Check the length of the wire to verify that it is long enough to reach to the top of the plug well. My Stelvio had more than enough wire on both left and right cylinder to easily reach the plug well. If the left side is too short, you can re-route the wire around the frame member, shown here near the coil, to gain more slack.

Note that the plug wire is routed inside a protective plastic conduit. While performing this task, I discovered one of my conduits filled with water. To make sure water will drain from the conduit and to give enough wire exposure for fitting the new spark plug cap, cut back the protective conduit about an inch and a half or 35-40 mm.

I suggest removing the weather seal boot from the NGK cap instead of trying to insert the wire through it.

The wire end of the NGK replacement cap showing the male threads that go up into the plug wire end in order to make electrical contact.

Slip the sealing boot onto the plug wire. Then, hold the wire and cap firmly. Insert the wire end into the cap and screw the wire onto the male threads inside the cap. The male threads screw up into the metal wire conductor in the center of the insulated plug wire.

Work the rubber sealing boot onto the plastic plug cap and insert the cap down into the valve cover until it snap snugly onto the spark plug. A small amount of dielectric grease on the plug insulator or the inside of the sealing boot will help.

Fit the wire down into the holding area and install the silver cover with the small screw and reinstall the snap-in MG logo piece. A good idea is to apply some silicone or glue under the logo badge to make sure it does not vibrate out.