All,

Going to come out of the dark for a bit as I feel it is important to communicate a recent finding on a 2013 Stelvio with apparent charging issues. This could easily be an issue on any other 8V motor so not specific to the Stelvio.

Please don't respond with not possible or try to argue any facts on the notes below. This is from first hand experience with the bike and seeing it with my own eyes and testing it with my own meter. All the electrical paths in my previous thread concerning the lighting relay and HB relay are verified accurate so please don't tell me something that is not there like the HB handlebar switch is responsible for charging issues.

One of the members on the forum (I will leave it to him if he wants to be identified) contacted me via PM as he had a charging issue with his bike. SInce I had laid out the electrics in a previous thread he thought I could help him with fixing his bike.

Symptoms

At this point I was intrigued and packed up my tools and electrical diagnostics and repair items. Luckily he was only an hour ride from my place.

I spent a hour or so testing and retesting the paths and nothing made sense at that time. The most curious thing was that when the bike was running, the power to the 30amp fuse (and therefore the lighting relay) was gone. When it was just the key on, the power was there.

Turns out the splice between the 40 amp and 30 amp fuses is at the actual alternator. Both wires are crimped into a ring terminal that is screwed to the alternator. The ring terminal insulation was completely burnt along with about 2 inches of wire. Turned it to dust.

Had just enough connection to give readings when the key was on, but once the bike was started and the vibrations set in, the connection was broke. This resulted in increased resistance and a crap load of heat. If this had continued and not broken completely when the bike was running it would have resulted in a meltdown under the gas tank. He did say that he swore he saw some puffs of smoke on the last ride by though he was imagining things, as we all have. The crimp on the ring terminal was marginal at best. I am not even sure it was there to begin with. This was not a corrosion issue as the wires themselves and the insulation were completely burnt. There is also nothing to ground to where these wires are and they are protected by a long boot so it was not a small short to ground

Installed a new ring terminal and made sure the crimp was secure. Fired up and had full charging and lights.

This is something to be aware of it you start to have charging and light issues and the 30amp fuse and relays are still good. Easiest check is to check the resistance between the 30 amp red/green wire (one behind the right hand panel under the seat) and the 40 amp red green wire (40 amp next to the air box). It should be pretty much 0 to 0.1 ohm. Then check the resistance of each of those wires to the +ve on the battery. Should again be 0 to 0.1 ohms. Any resistance much higher than those numbers (subtracting the resistance of the actual meter wires) indicate a problem developing and you should be checking that connection at the alternator.

Thanks

Joe

Going to come out of the dark for a bit as I feel it is important to communicate a recent finding on a 2013 Stelvio with apparent charging issues. This could easily be an issue on any other 8V motor so not specific to the Stelvio.

Please don't respond with not possible or try to argue any facts on the notes below. This is from first hand experience with the bike and seeing it with my own eyes and testing it with my own meter. All the electrical paths in my previous thread concerning the lighting relay and HB relay are verified accurate so please don't tell me something that is not there like the HB handlebar switch is responsible for charging issues.

One of the members on the forum (I will leave it to him if he wants to be identified) contacted me via PM as he had a charging issue with his bike. SInce I had laid out the electrics in a previous thread he thought I could help him with fixing his bike.

Symptoms

- Had no headlights, high beam or low beam with the bike running, however from time to time they would come on.

- When headlights did work, there was no charging or the voltage was at a very low level (ie 12V or so) but did not seem to go lower.

- No charging with headlights on or off

- This continued sporadically for some time but the bike never died or left him stranded.

- Replace the battery with a MotoBatt but the problems still continued

- Had the obligatory no head lights, no charging and blue HB light when the momentary HB switch was pulled.

- 30 amp fuse was good.

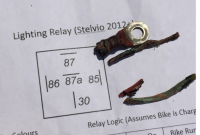

- Voltages on terminal 30 and 87 on the lighting relay were sporadic. Voltage one minute, no voltage the next. Even when 30 (main relay power from 30 amp fuse) and 87 (exciter power and lighting power) had power there was no charging or lights which at that time seemed impossible for the lights as 87 is pretty much a direct line to the lights as long as the HB relay is working (and it was confirmed as working)

At this point I was intrigued and packed up my tools and electrical diagnostics and repair items. Luckily he was only an hour ride from my place.

I spent a hour or so testing and retesting the paths and nothing made sense at that time. The most curious thing was that when the bike was running, the power to the 30amp fuse (and therefore the lighting relay) was gone. When it was just the key on, the power was there.

- Tested resistance of the 30 amp fuse power supply wire (red green) to the +ve on the battery and it had continuity (0.1 ohm resistance)

- Tested continuity of the 40 amp fuse power supply (green/red) that is for the charging power to the +ve on the battery and it had a resistance of 280 ohm. This should be zero to the battery.

- Tested continuity between the above two wires which are spliced together as some point (brings battery power and charging power to the bike) and had continuity.

- Jumped power to the 30 amp fuse directly from the battery which powered the 87 terminal on the lighting relay (ie. power to headlights and alternator exciter) and the headlights came on when the bike was running, but no charging.

Turns out the splice between the 40 amp and 30 amp fuses is at the actual alternator. Both wires are crimped into a ring terminal that is screwed to the alternator. The ring terminal insulation was completely burnt along with about 2 inches of wire. Turned it to dust.

Had just enough connection to give readings when the key was on, but once the bike was started and the vibrations set in, the connection was broke. This resulted in increased resistance and a crap load of heat. If this had continued and not broken completely when the bike was running it would have resulted in a meltdown under the gas tank. He did say that he swore he saw some puffs of smoke on the last ride by though he was imagining things, as we all have. The crimp on the ring terminal was marginal at best. I am not even sure it was there to begin with. This was not a corrosion issue as the wires themselves and the insulation were completely burnt. There is also nothing to ground to where these wires are and they are protected by a long boot so it was not a small short to ground

Installed a new ring terminal and made sure the crimp was secure. Fired up and had full charging and lights.

This is something to be aware of it you start to have charging and light issues and the 30amp fuse and relays are still good. Easiest check is to check the resistance between the 30 amp red/green wire (one behind the right hand panel under the seat) and the 40 amp red green wire (40 amp next to the air box). It should be pretty much 0 to 0.1 ohm. Then check the resistance of each of those wires to the +ve on the battery. Should again be 0 to 0.1 ohms. Any resistance much higher than those numbers (subtracting the resistance of the actual meter wires) indicate a problem developing and you should be checking that connection at the alternator.

Thanks

Joe

Last edited: