kinkajou

Tuned and Synch'ed

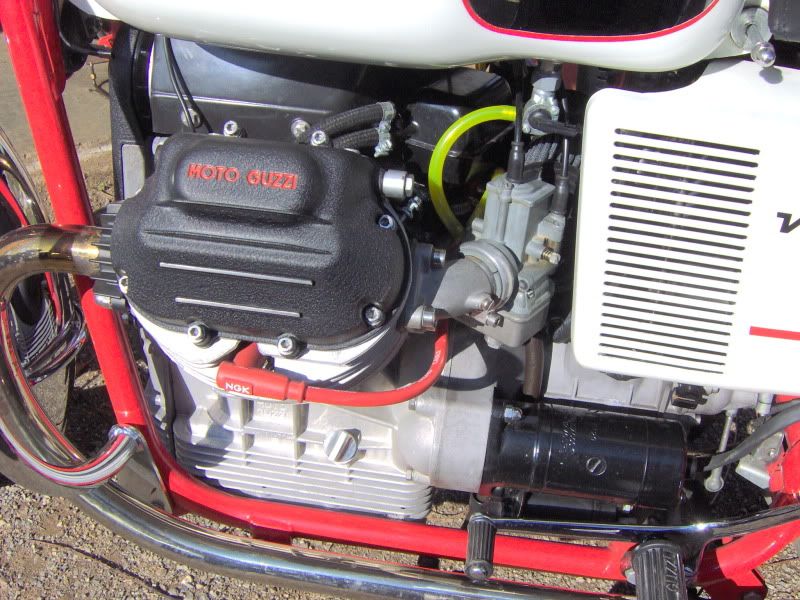

Hi, Im planning to sandblast my Eldo's engine....somebody did that before without stripping the engine? just plugging every holes should be fine right? or do I really have to stip it....dont really want to , It runs just perfec like that.... Any help apreciated...Thanks