iainw

Cruisin' Guzzisti

05 Breva 1100

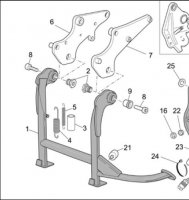

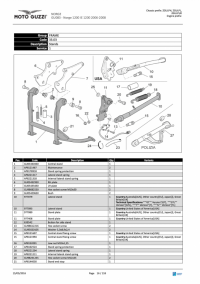

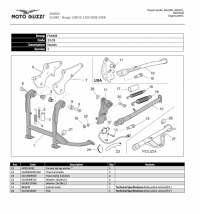

My centre stand, lower pannier brackets, and one or two other bits are starting to look a bit tatty so they're going off to be powder coated. I'd like to remove the centre stand without taking the whole lot apart but the cat is a bit close on the r/h side to get a spanner in where it pivots on (2), so the job looks a bit bigger than I originally thought. The whole lot is going to have to come off so that I can get a good grip and remove items (2).

I've undone the hex screw (8) at the r/h side and it comes out, (2) seems to be screwed into the stand mounting plate (6) but I can't get a spanner on it as the cat is too close.

On the l/h side I can't remove (8) from (2) they're just turning with the bush (9). I haven't yet put a spanner on (2) to hold it. I'm just weighing the job up at the moment.

Before I start taking the whole bike apart, grazing knuckles and damaging bits my question is, do items (2) thread into (6) & (7) or do they rotate in there? On the r/h it's not rotating and appears to be threaded in and on the l/h side it turns with (8) & (9) and appears not to be threaded in. How does all this lot fit together?

my question is, do items (2) thread into (6) & (7) or do they rotate in there? On the r/h it's not rotating and appears to be threaded in and on the l/h side it turns with (8) & (9) and appears not to be threaded in. How does all this lot fit together?

Ta very much.

Iain

My centre stand, lower pannier brackets, and one or two other bits are starting to look a bit tatty so they're going off to be powder coated. I'd like to remove the centre stand without taking the whole lot apart but the cat is a bit close on the r/h side to get a spanner in where it pivots on (2), so the job looks a bit bigger than I originally thought. The whole lot is going to have to come off so that I can get a good grip and remove items (2).

I've undone the hex screw (8) at the r/h side and it comes out, (2) seems to be screwed into the stand mounting plate (6) but I can't get a spanner on it as the cat is too close.

On the l/h side I can't remove (8) from (2) they're just turning with the bush (9). I haven't yet put a spanner on (2) to hold it. I'm just weighing the job up at the moment.

Before I start taking the whole bike apart, grazing knuckles and damaging bits

Ta very much.

Iain