Daniel Kalal

Cruisin' Guzzisti

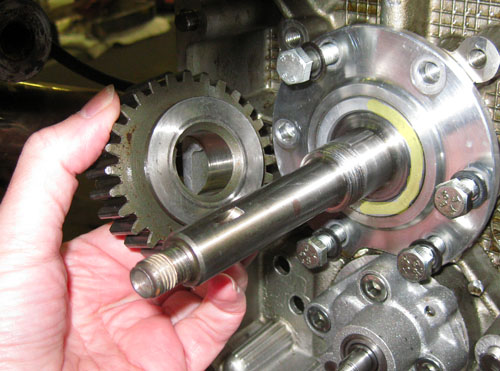

A head-scratcher.

In the photograph, you can see the steel gear that was removed from the crank as part of the conversion from gears to chain. But, here's the deal: It was found that when the new sprocket was torqued, it pulled up against the bearing surface before it did the crank. So we tried the old steel gear. The tolerances are very slight, but even when the steel gear was put back, the same thing happened. The engine did turn before things were removed, although there is evidence on the face of the gear that things were always very, very close.

Note: I've shaded part of the bearing face yellow in the photograph (it's not really that color).

So, what is going on here? Why isn't it pulling up flush?

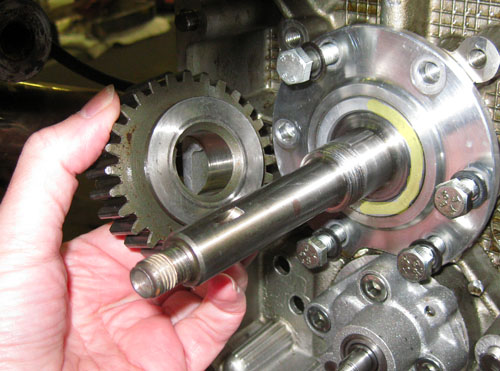

By the way; this is what the aluminum oil pump gear looked like:

In the photograph, you can see the steel gear that was removed from the crank as part of the conversion from gears to chain. But, here's the deal: It was found that when the new sprocket was torqued, it pulled up against the bearing surface before it did the crank. So we tried the old steel gear. The tolerances are very slight, but even when the steel gear was put back, the same thing happened. The engine did turn before things were removed, although there is evidence on the face of the gear that things were always very, very close.

Note: I've shaded part of the bearing face yellow in the photograph (it's not really that color).

So, what is going on here? Why isn't it pulling up flush?

By the way; this is what the aluminum oil pump gear looked like: