Damn brother, if I could only weld.... It's one of those things (along with automotive wiring) that I'm struggling to master. It's just not my cup of tea. I really wanted to splash sm cash on titanium tubing for that exhaust but I knew that it's far beyond my skillset. Heck, I'm glad that I even didn't go for stainless LOL Pictures doesn't do the justice, I can ensure you my welds are a lot to be desiredMindis, ive drooled over your thread here and im very impressed at your skill set! Hell all I can do is weld... I'm not worthy!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Ciao Guest - You’ve landed at the ultimate Guzzi site. NEW FORUM REGISTRATIONS REQUIRE EMAIL ACTIVATION - CHECK YOUR SPAM FOLDER - Use the CONTACT above if you need help. New to the forum? For all new members, we require ONE post in the Introductions section at the bottom, in order to post in most of the other sections. ALWAYS TRY A SEARCH BEFORE STARTING A NEW TOPIC - Most questions you may have, have likely been already answered. DON'T BE A DRIVE-BY POSTER: As a common courtesy, check back in and reply within 24 hours, or your post will be deleted. Note there's decades of heavily experienced Guzzi professionals on this site, all whom happily give endless amounts of their VALUABLE time for free; BE COURTEOUS AND RESPECTFUL!

-

There is ZERO tolerance on personal attacks and ANY HYPERLINKS to PRODUCT(S) or other competing website(s), including personal pages, social media or other Forums. This ALSO INCLUDES ECU DIAGnostic software, questions and mapping. We work very hard to offer commercially supported products and to keep info relevant here. First offense is a note, second is a warning, third time will get you banned from the site. We don't have the time to chase repeat (and ignorant) offenders. This is NOT a social media platform; It's an ad-free, privately funded website, in small help with user donations. Be sure to see the GTM STORE link above; ALL product purchases help support the site, or you can upgrade your Forum profile or DONATE via the link above.

-

Be sure to see the GTM STORE link also above for our 700+ product inventory, including OEM parts and many of our 100% Made-in-SoCal-USA GTM products and engine kits. In SoCal? Click the SERVICE tab above for the best in service, tires, tuning and installation of our products or custom work, and don't miss our GT MotoCycles® (not) art on the BUILDS tab above. WE'RE HERE ONLINE ONLY - NO PHONE CALLS MADE OR RECEIVED - DO NOT EMAIL AND ASK QUESTIONS OR ASK TO CALL YOU.

-

Like the new V100, GuzziTech is full throttle into the future! We're now running on an all-new server and we've updated our Forum software. The visual differences are obvious, but hopefully you'll notice the super-fast speed. If you notice any glitches or have any issues, please post on the Site Support section at the bottom. If you haven't yet, please upgrade your account which is covered in the Site Support section or via the DONATE tab above, which gives you full site access including the DOWNLOADS section. We really appreciate every $ and your support to keep this site ad-free. Create an account, sign in, upgrade your account, and enjoy. See you on the road in 2024.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mindis V7-850 Mods

- Thread starter Mindis

- Start date

Dam nice looking Filler cap!

Last time i filled er up, that flap that slips out of the way to let the key in was bent , causing a bit of Alarm for a few moments.

Thats a nice tidy little solution !

Last time i filled er up, that flap that slips out of the way to let the key in was bent , causing a bit of Alarm for a few moments.

Thats a nice tidy little solution !

Last edited:

Looking forward to a startup and drive by sound clip of the pipes

davethewelder

Cruisin' Guzzisti

Titanium requires lots and lots of skill and you'll need to purge with Argon just like SS. I dont even do Titanium at my shop, few guys come here with Titanium exhaust, I won't repair them, basically requires a proper match of filler wire and different Gas lenses or cups... If I was building an exhaust I'd prolly just use SS and my pipe bender.Damn brother, if I could only weld.... It's one of those things (along with automotive wiring) that I'm struggling to master. It's just not my cup of tea. I really wanted to splash sm cash on titanium tubing for that exhaust but I knew that it's far beyond my skillset. Heck, I'm glad that I even didn't go for stainless LOL Pictures doesn't do the justice, I can ensure you my welds are a lot to be desired

Titanium requires lots and lots of skill and you'll need to purge with Argon just like SS. I dont even do Titanium at my shop, few guys come here with Titanium exhaust, I won't repair them, basically requires a proper match of filler wire and different Gas lenses or cups... If I was building an exhaust I'd prolly just use SS and my pipe bender.

I myself have never understood the desire to have a titanium exhaust (or any obscure or rare metal or even pure carbon fiber) for this very specific reason. It is almost impossible to get repaired and if you can find somebody to do it properly, then it will cost a fortune to have it done.

If I were to build an exhaust from scratch, then I would use common steel and then have it ceramic coated inside and out. It would last forever and if it was damaged, any welder could repair it and it could easily be ceramic coated again.

I don't like exotic materials for just this reason. Steel and aluminum are my choices for virtually anything I fabricate.

But how can you get the Cool Purple colors if you Don't use Titanium !

from the web-

“According to relevant research, after heating in the air for half an hour, the titanium surface heated at 200 ℃ is silver white, 300 ℃ is light yellow, 400 ℃ is golden yellow, 500 ℃ is blue and 600 ℃ is purple, 700 ℃ (to) - 800 ℃ is grayish red, 900 ℃ is gray, and the whole color change is colorful.”

from the web-

“According to relevant research, after heating in the air for half an hour, the titanium surface heated at 200 ℃ is silver white, 300 ℃ is light yellow, 400 ℃ is golden yellow, 500 ℃ is blue and 600 ℃ is purple, 700 ℃ (to) - 800 ℃ is grayish red, 900 ℃ is gray, and the whole color change is colorful.”

Last edited:

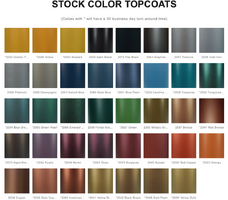

Oddly ( to me at least ) when I had the aluminium injector covers powder coated, I thought they could mix powder to get Any color they wanted, but it was not so ;(

They had to order the color and texture to match the valve covers.

They did 2 or 3 tests to make sure they had the best match, before they did the job.

I wonder if ceramic coat is the same ?

Eg: baked / melted powder ?

They had to order the color and texture to match the valve covers.

They did 2 or 3 tests to make sure they had the best match, before they did the job.

I wonder if ceramic coat is the same ?

Eg: baked / melted powder ?

Oddly ( to me at least ) when I had the aluminium injector covers powder coated, I thought they could mix powder to get Any color they wanted, but it was not so ;(

They had to order the color and texture to match the valve covers.

They did 2 or 3 tests to make sure they had the best match, before they did the job.

I wonder if ceramic coat is the same ?

Eg: baked / melted powder ?

Not even remotely the same. Powder coating is paint. Ceramic coating is just that, a high temperature ceramic material that fuses on a molecular level with the metal. It is about 1000x more durable than paint.

In order to meet Original Equipment Manufacturer (OEM) ceramic coating anti-chip requirements, the surface must withstand a pebble shot at the coated surface at 95 mph from a distance of 32 inches away.

Powder coating can be applied to used parts after they have been degreased and then chemically cleaned to provide a proper surface for the electrostatically paint coating to be applied. The part is then placed in an oven for 15-30 minutes to complete the process. Typical cure temperature on Powder Coating is 350-425 degrees.

Ceramic coating comes in two applications; Dip-Spin and traditional wet spray application. Dip-Spin is most often used with large quantities of small to medium size parts. The parts are surface prepped and placed in a bin with perforated sides and bottom. The bin is then dipped in another larger bin containing the liquid ceramic coating, lifted out of the larger bin and spun to sling excess coating off the parts. This lowers waste of coating and allows large quantities of parts to be evenly coated at a single time. Once this process is done, the parts are run through a very large oven to fully cure them - 750 degrees for 3-5 hours.

Last edited:

I recorded stock muffler sound with DB meter app, will do the same after I fire her up. I'll load a video hereLooking forward to a startup and drive by sound clip of the pipes

My Irish and UK friends will know the add from Tesco (Wallmart equivalent)- "Every little helps!". And my aim here is power to weight ratio. No, I don't want another bike that has more power, I love my V7 to bits, but I want to squeeze everything I can out of it. There goes a question that each person has a different answer- how far will you go with your mods??? Personally I'll go without any limits. If I can shave half a kilo, I will. I'll spend whatever hours it takes to make something (and I'm getting a stiffy while at it LOL) just to have that something a little bit lighter, smaller, better looking in my eyes. Powerwise there's not much I can do until big bore kit shows up (hopefully, hehe) but with my little things there and there I'll drop quite a bit of weight. So if I had the skillset for welding titanium, I'd be making my exhaust from titanium without a doubt. That'd be very costly, but less then half the weight of my mild steel one, which already feels featherlight compared to original exhaustI myself have never understood the desire to have a titanium exhaust (or any obscure or rare metal or even pure carbon fiber)

You like modification! Tattoos, piercings, and virtually everything on your motorcycle!

I think it makes you very unique!

Everybody here is totally impressed with your mad skills. You get the ovation for sure!

I think it makes you very unique!

Everybody here is totally impressed with your mad skills. You get the ovation for sure!

Mindis..

Just the other day when I was talking to Todd we were saying what an artist you are with the forged carbon ....

Three thumbs up

Just the other day when I was talking to Todd we were saying what an artist you are with the forged carbon ....

Three thumbs up

Mindis, you are mod'ing your bike so fast it's hard to keep up with the reading .

.

I wrapped the headers on my Buell 7 years ago to cover a dent. Lordco Autoparts offered a coating by D.E.I. that sprays on and cures to a fibreglass like finish. Comes in several colours incl. black. Called High Temp Silicone Coating. I chose silver, and the wrap has never frayed. My wrap still looks like brand new.

I wrapped the headers on my Buell 7 years ago to cover a dent. Lordco Autoparts offered a coating by D.E.I. that sprays on and cures to a fibreglass like finish. Comes in several colours incl. black. Called High Temp Silicone Coating. I chose silver, and the wrap has never frayed. My wrap still looks like brand new.

Well fluff, too late now, it's half wrapped and temporary on the bike. I have only very little time off this Xmas so I have to get my stuff rolling... I need to have it on for making kickstand and belly panMindis, you are mod'ing your bike so fast it's hard to keep up with the reading.

I wrapped the headers on my Buell 7 years ago to cover a dent. Lordco Autoparts offered a coating by D.E.I. that sprays on and cures to a fibreglass like finish. Comes in several colours incl. black. Called High Temp Silicone Coating. I chose silver, and the wrap has never frayed. My wrap still looks like brand new.

Thanks for info, I'll definitely look into it

I picked up some clear high temp silicone spray to cover the wrap on the Honda, masked off the bike from the spray area with a LOT of news paper.

It helped hold it together but went gray after while, I should have used black

It helped hold it together but went gray after while, I should have used black

Center stand, the failed attempt. Well, not as failed but my time wasted. Thought I'll share it anyway...

Started with brackets and legs on frame's cross member where evap can used to sit:

My "fancy" way of bending tubes:

I found my 10mm, all of them!!! I wanted pads to look a bit like my personal logo:

I wanted pads to look a bit like my personal logo:

And looks like I'm nearly done, but...

...but I don't like it

My idea was for legs to be hiding behind mufflers, nearly invisible with only pads sticking out behind muffler exits. When I was roughly checking measurements and clearances it all looked good at the time but in the end my center stand came out too long for my liking... It works, it does it's job good so technically I didn't fail, but it's legs are sticking out way too far past mufflers when folded up. In my eyes it looks out of place and out of proportion. I can't have them shorter coz I have barely an inch from the ground to rear wheel when center stand is down. I don't want to shorten legs and make brackets longer (aka move pivot point down) coz it would end up lower then mufflers. My bike is already lowered enough.

I spent lots of hours on it and now I'll discard it and brainstorm of another plan, oh well...

Started with brackets and legs on frame's cross member where evap can used to sit:

My "fancy" way of bending tubes:

I found my 10mm, all of them!!!

And looks like I'm nearly done, but...

...but I don't like it

My idea was for legs to be hiding behind mufflers, nearly invisible with only pads sticking out behind muffler exits. When I was roughly checking measurements and clearances it all looked good at the time but in the end my center stand came out too long for my liking... It works, it does it's job good so technically I didn't fail, but it's legs are sticking out way too far past mufflers when folded up. In my eyes it looks out of place and out of proportion. I can't have them shorter coz I have barely an inch from the ground to rear wheel when center stand is down. I don't want to shorten legs and make brackets longer (aka move pivot point down) coz it would end up lower then mufflers. My bike is already lowered enough.

I spent lots of hours on it and now I'll discard it and brainstorm of another plan, oh well...

Why not put on real mufflers that extend a little further. Plenty of options in the store tab. A center stand is a very useful item.

They *are* real mufflers. They are the size I want and in exact place I want and they're not going any furtherWhy not put on real mufflers that extend a little further. Plenty of options in the store tab. A center stand is a very useful item.

I'm sick of welding atm so I'll jump on my favorite composites and get back to welding whenever I feel like LOL

Since I made my bumstop it was bugging me that it's kinda heavy. It's just a condom just slides on the seat but not to temper with original seat I had to make that way. Plastic part is heavy, foam is heavy, and I ride solo only, so I can replace all unnecessary stuff with air I'll make this one a wee bit narrower, my guess one third of the weight (or at least half definitely) and I have new taillight/signal unit that is much brighter than my bumstop's LED strip. I'll keep original seat for longer rides coz it's very comfy and new one zippin around.

I'll make this one a wee bit narrower, my guess one third of the weight (or at least half definitely) and I have new taillight/signal unit that is much brighter than my bumstop's LED strip. I'll keep original seat for longer rides coz it's very comfy and new one zippin around.

My plan is to do in 3 sections. Base, seat itself and bumstop. Base will be mainly cut out. Bumstop will be made as a shell and glued to the base. After that I'll make another small base just for the seat, which after upholstery will be bolted on. Seat part will be removable from the base in case I'll need to reupholster.

Covered all the stuff with fiberglass sheet scraps, taped, ready for fiberglass:

Only 2 layers of cloth as most of it will be holes, but reinforced sides where my butt is gonna sit, as well as extra layers to reinforce seat's latch area:

Since I made my bumstop it was bugging me that it's kinda heavy. It's just a condom just slides on the seat but not to temper with original seat I had to make that way. Plastic part is heavy, foam is heavy, and I ride solo only, so I can replace all unnecessary stuff with air

My plan is to do in 3 sections. Base, seat itself and bumstop. Base will be mainly cut out. Bumstop will be made as a shell and glued to the base. After that I'll make another small base just for the seat, which after upholstery will be bolted on. Seat part will be removable from the base in case I'll need to reupholster.

Covered all the stuff with fiberglass sheet scraps, taped, ready for fiberglass:

Only 2 layers of cloth as most of it will be holes, but reinforced sides where my butt is gonna sit, as well as extra layers to reinforce seat's latch area: