Hi everybody, longtime lurker, first time poster. I'm working on a 1971 Ambassador. I have the engine apart and I'm in the process of acquiring parts for a rebuild. I'm curious about a few things that I am finding, and having found no answers using the search, have some questions for the group:

1. How much camshaft end play is acceptable? With the bronze thrust bearing and timing gear in place, I measured 0.004" (~0.01mm). Is this acceptable, or does the thrust bearing need to be replaced? I should add that the distributor gear was pretty badly worn, but the wear was uneven, possibly due to poor heat-treatment? Or is this related to the camshaft end play being excessive?

2. I plan to install a new oil pump. How much wear on the engine block from the oil pump gears is acceptable? There are 2 circular patterns on the front machined surface that the oil pump bolts to. I can feel them with a fingernail. I have photos that I can post, but I can't do it at the moment. Will post the photos later.

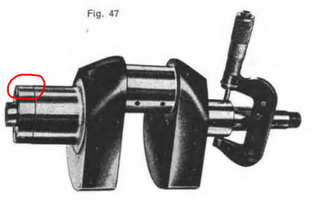

3. The sealing surface on the rear end of the crankshaft is damaged (gouged), probably by a whatever tool the previous mechanic was using to pull the oil seal. I'd like to use a repair sleeve, but the size tables I've found don't list a size that matches the micrometer reading that I'm getting. The end of the crankshaft that the seal rides on is reduced a bit from the main journal size, which appears to be 2.125" nominal. I measured the sealing surface diameter at 2.085". Repair sleeve size tables show #99205 (shaft size 2.057" - 2.063") and #99210 (2.122" - 2.128"). Will the #99205 stretch enough to fit? Has anybody else done this?

Thanks for helping with this.

Matt

1. How much camshaft end play is acceptable? With the bronze thrust bearing and timing gear in place, I measured 0.004" (~0.01mm). Is this acceptable, or does the thrust bearing need to be replaced? I should add that the distributor gear was pretty badly worn, but the wear was uneven, possibly due to poor heat-treatment? Or is this related to the camshaft end play being excessive?

2. I plan to install a new oil pump. How much wear on the engine block from the oil pump gears is acceptable? There are 2 circular patterns on the front machined surface that the oil pump bolts to. I can feel them with a fingernail. I have photos that I can post, but I can't do it at the moment. Will post the photos later.

3. The sealing surface on the rear end of the crankshaft is damaged (gouged), probably by a whatever tool the previous mechanic was using to pull the oil seal. I'd like to use a repair sleeve, but the size tables I've found don't list a size that matches the micrometer reading that I'm getting. The end of the crankshaft that the seal rides on is reduced a bit from the main journal size, which appears to be 2.125" nominal. I measured the sealing surface diameter at 2.085". Repair sleeve size tables show #99205 (shaft size 2.057" - 2.063") and #99210 (2.122" - 2.128"). Will the #99205 stretch enough to fit? Has anybody else done this?

Thanks for helping with this.

Matt