On a '73 750 engine:

Looking to advance a cam while using "stock" cam/crank/oilpump gears (not chain)

The timing gear has 52 teeth ... each tooth = about 6.92 degrees.

about 3 degrees or so desired ... about 1/2 or so tooth rotation.

Looks like the helical gears have the spiral in a convienient direction to shim between cam and gear to advance the cam (relative to crank).

Has anyone stablished the shim thickness to degree ratio?

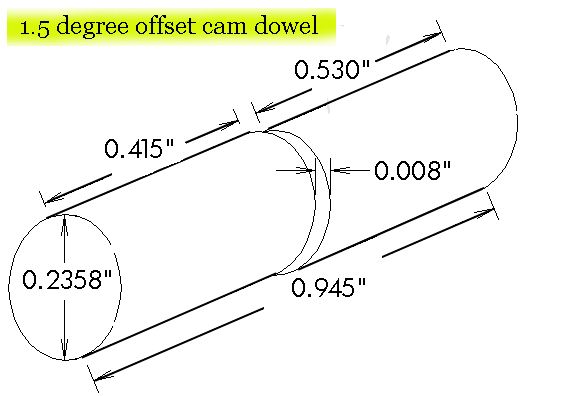

Or I could start looking for an offset pin I spoze. Or figure out how to make one... :unsure:

Alex

Looking to advance a cam while using "stock" cam/crank/oilpump gears (not chain)

The timing gear has 52 teeth ... each tooth = about 6.92 degrees.

about 3 degrees or so desired ... about 1/2 or so tooth rotation.

Looks like the helical gears have the spiral in a convienient direction to shim between cam and gear to advance the cam (relative to crank).

Has anyone stablished the shim thickness to degree ratio?

Or I could start looking for an offset pin I spoze. Or figure out how to make one... :unsure:

Alex