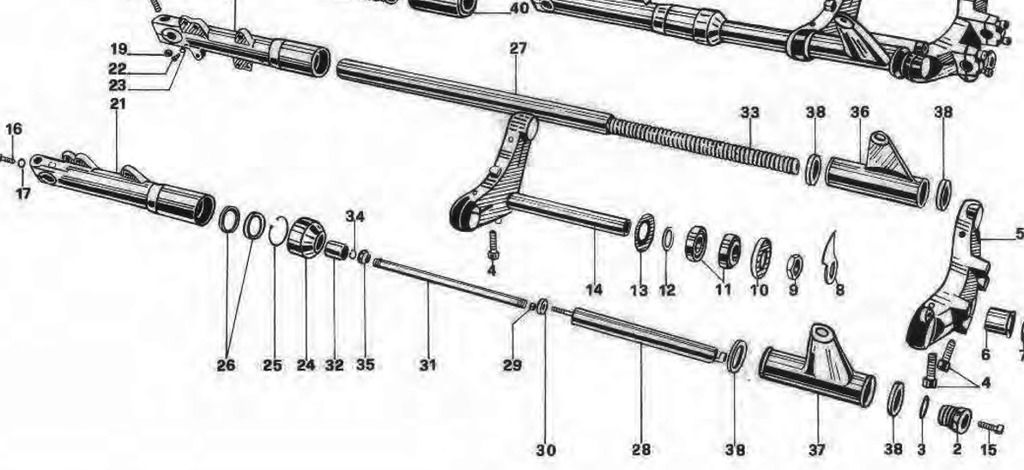

Anyone ever make/buy/find fork springs for V7 Sport that are about 305mm? I am considering lowering the front end by about 1.75" and need shorter, custom length, springs.

The front end of the oil pan is a bit higher than the rear end of the oil pan.

I'll hafta make shorter shock rods as well but that doesn't seem much of a show stopper.

Cutting a standard set of springs seems problematic. Tempering, shaping, hmmm.

next step is working on the human sail on top of the bike...

Alex

The front end of the oil pan is a bit higher than the rear end of the oil pan.

I'll hafta make shorter shock rods as well but that doesn't seem much of a show stopper.

Cutting a standard set of springs seems problematic. Tempering, shaping, hmmm.

next step is working on the human sail on top of the bike...

Alex