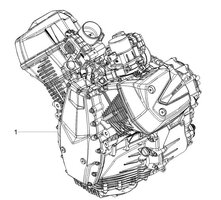

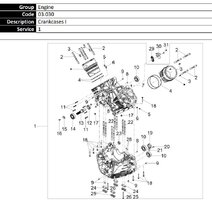

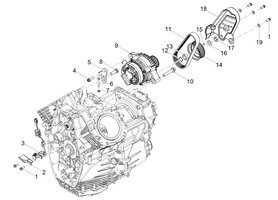

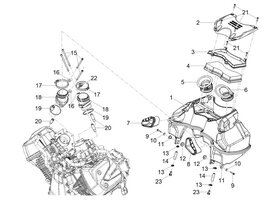

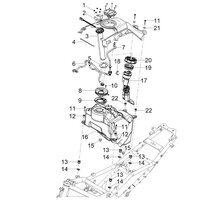

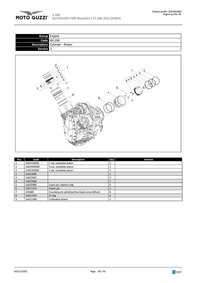

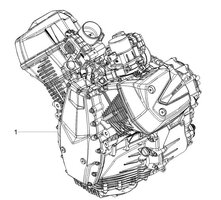

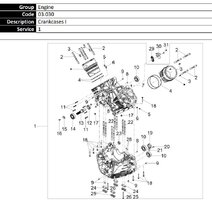

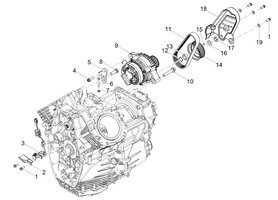

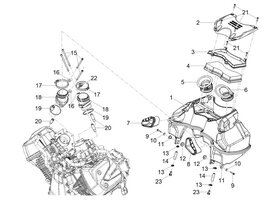

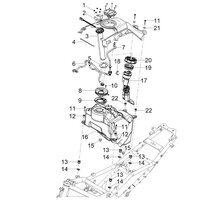

I just got ahold of the parts PDF for the V100 (now in the DOWNLOADS section), and I saw my first major disappointment with the engine. The cylinders are part of the engine cases, which if any of those here know of the past failures of some of the other major brands using this "design" (Honda VTR-1000 is one), it's never a good ending, Hopefully Guzzi is far smarter than Honda with durability. Also, this makes it NEARLY impossible for easy bigger displacement options. They moved the alternator rearward (behind the throttle bodies), but it does look to be of the same spec as the CARC models, which is a plus. The vast majority of the fuel tank looks to be the air box, which was another concern since I haven't seen capacity specs yet, and it looks like the tank is plastic and resides behind the air box. I has hoping for more clever placement.

Edit: I originally said… I'm still buying one of course. BUT Piaggio thought it was best to try and take down this website, weeks prior to the V100’s arrival, which cost me thousands of $’s - So Piaggio.

Piaggio.

Edit: I originally said… I'm still buying one of course. BUT Piaggio thought it was best to try and take down this website, weeks prior to the V100’s arrival, which cost me thousands of $’s - So