Flyscreen, windshield, windscreen, bugscreen, headlight cowl, whatever ya call it... My girlfriend called it giant toenail and got me triggered LOL

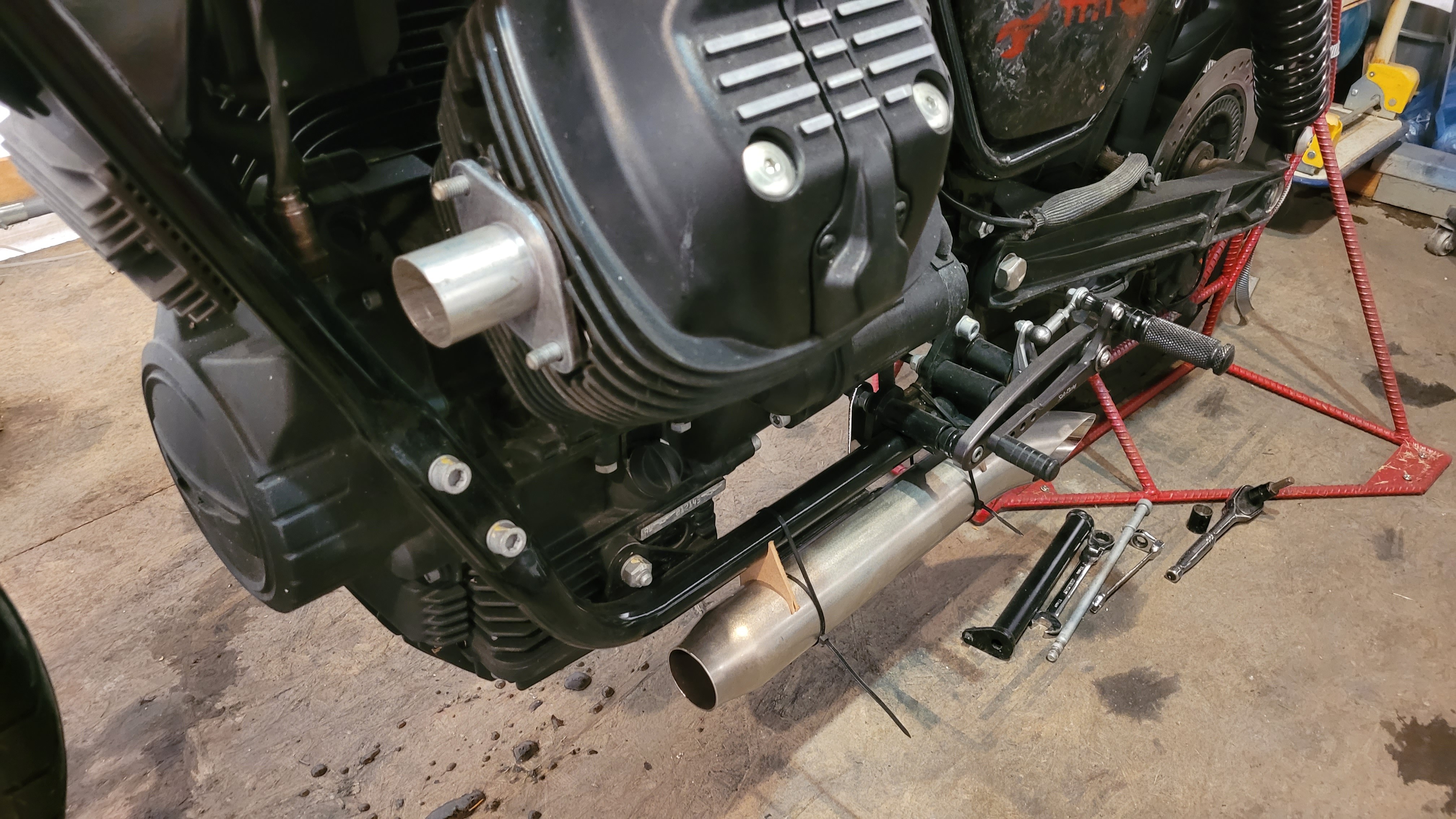

Mainly it's for visual for me to hide excess cables in front of my speedo but as I found out later it somewhat works as windshield as well. Now, to some it might look that my DYI'ing methods and processes are a bit scabby and unprofessional. To me it's the end result that matters and as I build only one-offs just for myself I don't want to waste time and money on making proper molds. My engineer/mechanic neighbor calls me innovative and resourceful but according to BS Translate it's cheapskate

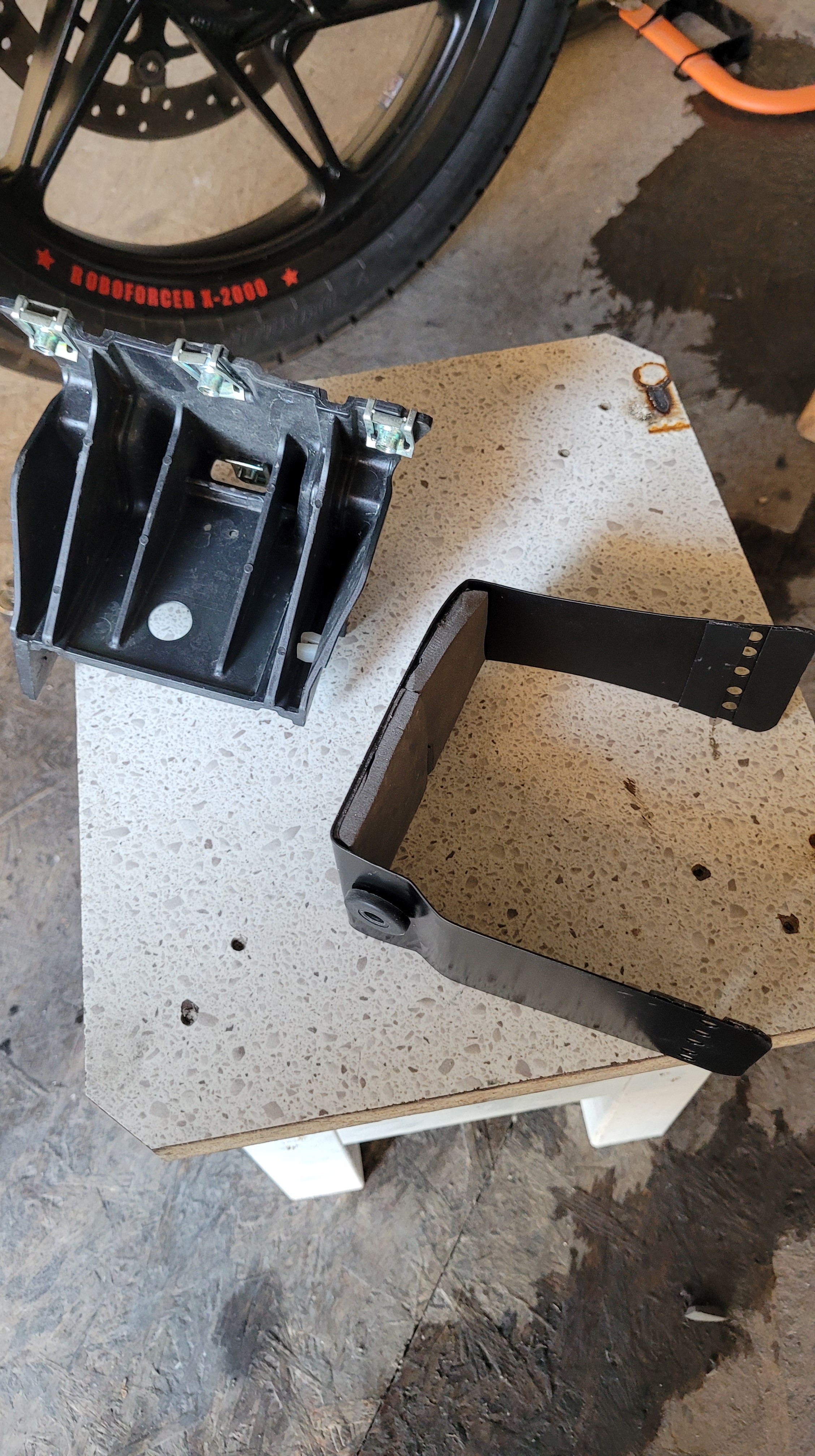

So I opened a beer, stole sm popsicle sticks from my kids and went crafting with hot glue gun:

I sculpted with sticks coz I wanted to be as tight and small as I can get. After that I took contraption off, sprayed expandable foam, shaped and put fiberglass layer on for rigidity for next step of bodywork:

I call it "bondo camo", it's like an artwork for me, some things I'd just hang on my walls...LOL

2 layers of carbon fiber cloth on the inside and carbon chop strands of the looks on the outside:

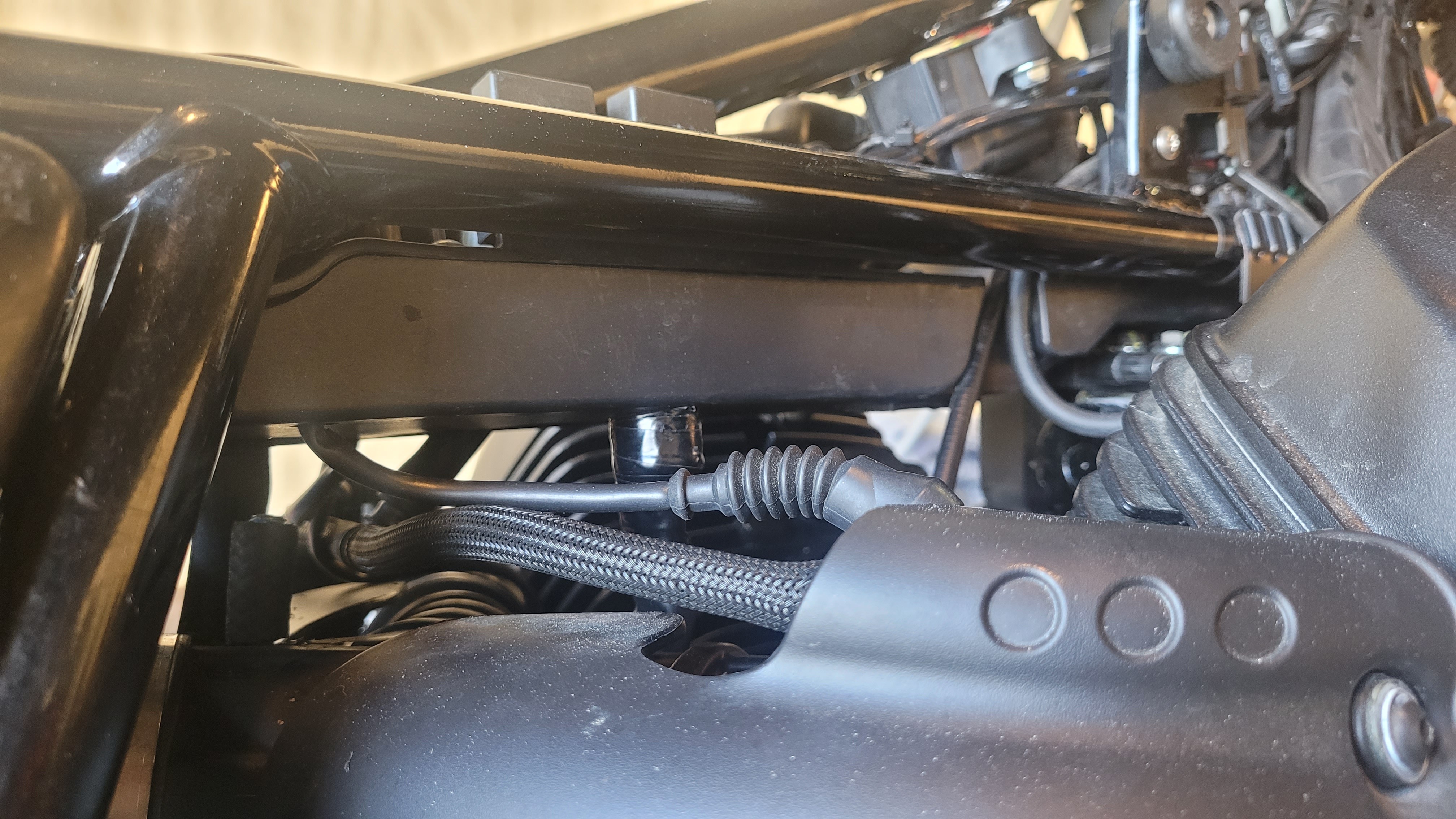

When shaping it I wanted my front line to flow together with tank's front line, that's why I pushed bottom of flyscreen a bit forward, few mm overlapping on top of my headlight:

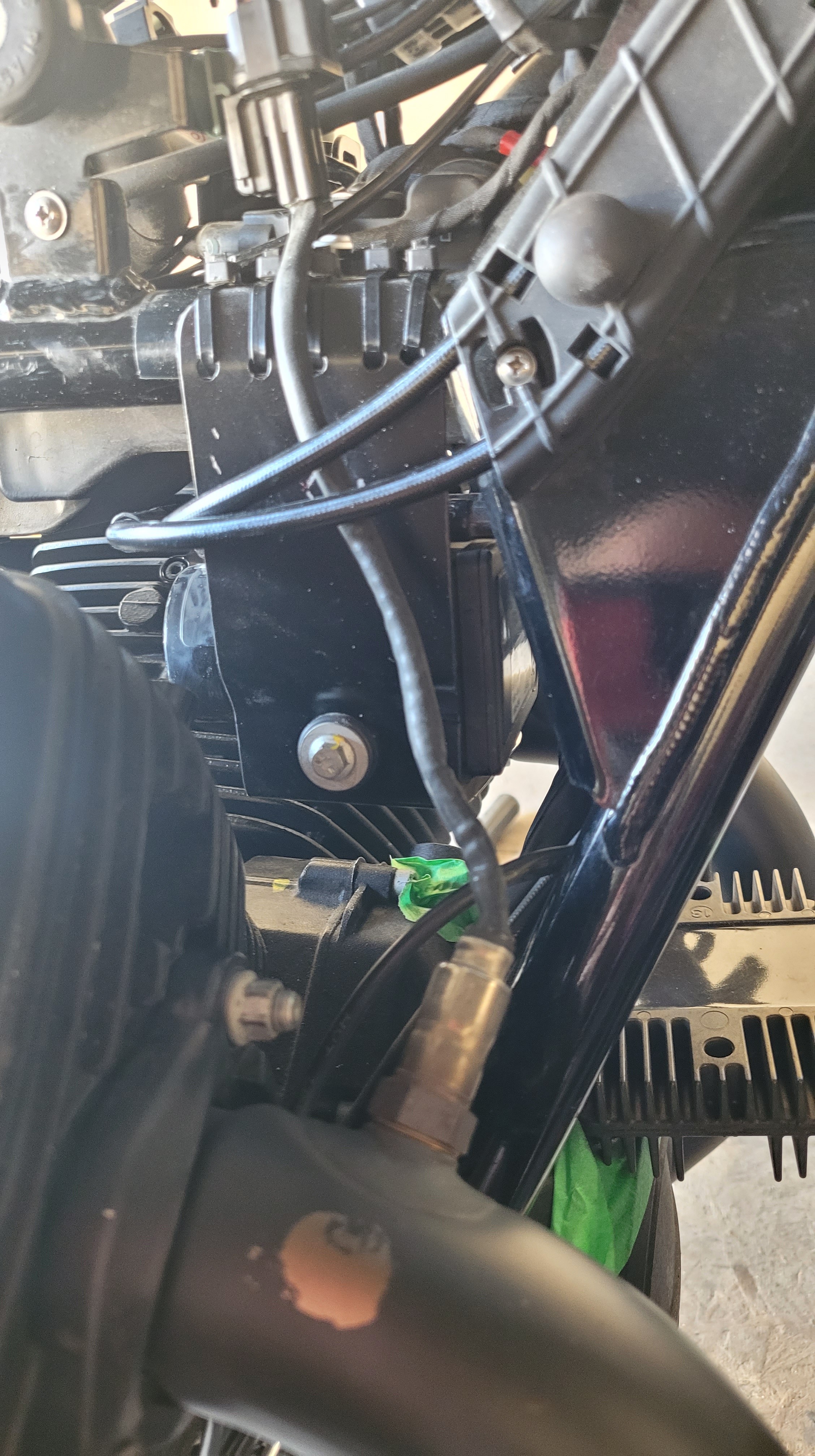

I also made it's mounting bracket so I can tilt it forward for steeper angle for longer highway rides for better wind shelter:

Shortly after I went for a rip to test it. Without flyscreen main wind stream was in my chin area at 140kmh. Up to 110kmh makes no difference. Now with this flyscreen main wind stream at 140kmh goes to my visor/top helmet area. Also it created some sort of "less wind tunnel" to the sides of my helmet. My noisy Scorpion Exo Evo became not as noisy As I mentioned wind protection wasn't my intentions but I'll take that extra win

As I mentioned wind protection wasn't my intentions but I'll take that extra win

Few more pics in sunshine

Mainly it's for visual for me to hide excess cables in front of my speedo but as I found out later it somewhat works as windshield as well. Now, to some it might look that my DYI'ing methods and processes are a bit scabby and unprofessional. To me it's the end result that matters and as I build only one-offs just for myself I don't want to waste time and money on making proper molds. My engineer/mechanic neighbor calls me innovative and resourceful but according to BS Translate it's cheapskate

So I opened a beer, stole sm popsicle sticks from my kids and went crafting with hot glue gun:

I sculpted with sticks coz I wanted to be as tight and small as I can get. After that I took contraption off, sprayed expandable foam, shaped and put fiberglass layer on for rigidity for next step of bodywork:

I call it "bondo camo", it's like an artwork for me, some things I'd just hang on my walls...LOL

2 layers of carbon fiber cloth on the inside and carbon chop strands of the looks on the outside:

When shaping it I wanted my front line to flow together with tank's front line, that's why I pushed bottom of flyscreen a bit forward, few mm overlapping on top of my headlight:

I also made it's mounting bracket so I can tilt it forward for steeper angle for longer highway rides for better wind shelter:

Shortly after I went for a rip to test it. Without flyscreen main wind stream was in my chin area at 140kmh. Up to 110kmh makes no difference. Now with this flyscreen main wind stream at 140kmh goes to my visor/top helmet area. Also it created some sort of "less wind tunnel" to the sides of my helmet. My noisy Scorpion Exo Evo became not as noisy

Few more pics in sunshine