Penis Rotor

GT Godfather!

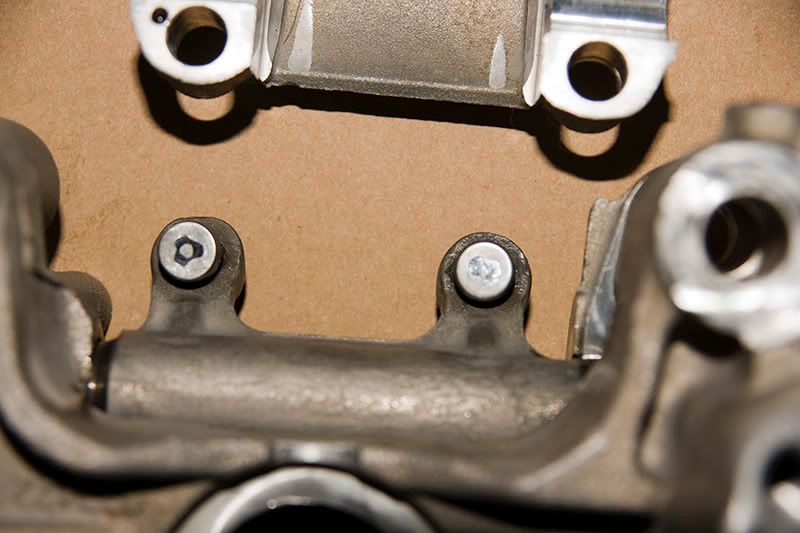

Doesn't show you what happens in the heads though. I'd better take some pics.

pete

pete

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

According to this the high pressure inner pump lubricates the heads. :? But stranger things have appeared in English translations of the Italian original.DanPez said:I wouldn't know how valid this information is but our sister forum "Guzzitek" has this document concerning the oil system.

http://guzzitek.org/documents/divers/Motor1200_8V_Course_(GB).pdf

The pump has 2 different delivery lines with a checklist what is being fed.

So, the oil is pressed up the same holes that the studs come through to compress the cylinder-head assembly on the engine cases? Are the studs "wet" by oil around them or do I get it wrong?pete roper said:... the oil for the camboxes comees from the high pressure circuit whiich is fed from the block up to the heads via the stud galleries ...

"Elementary, my dear Watson"...pete roper said:Cams spin at 1/2 crank speed, they have to be pressure fed

Mi_ka said:"Elementary, my dear Watson"...pete roper said:Cams spin at 1/2 crank speed, they have to be pressure fed

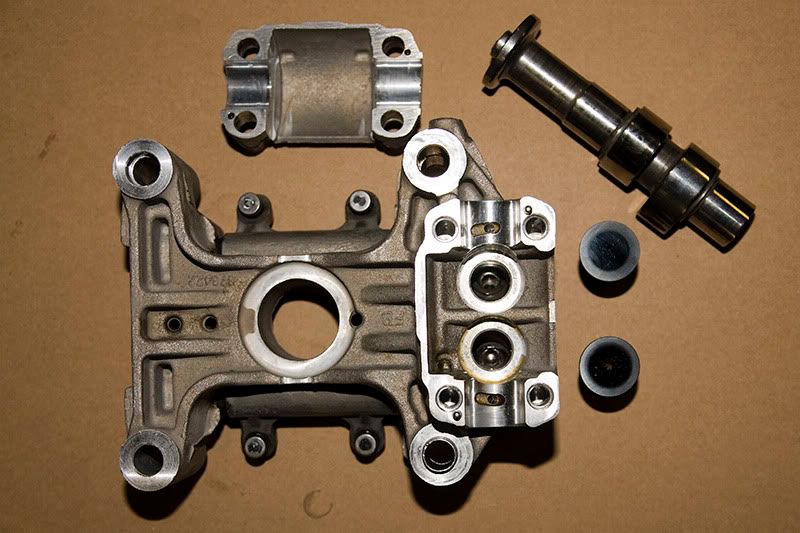

Still I do not get how the pressure line travels beside the studs. A picture/diagram would help my peanut brain.

pete roper said:That means that the oil not only for the bearings but also the cam bath HAS to come up the studs from the crankcase. And that opens up a whole different can of worms.

Pette

pete roper said:klaas123 said:

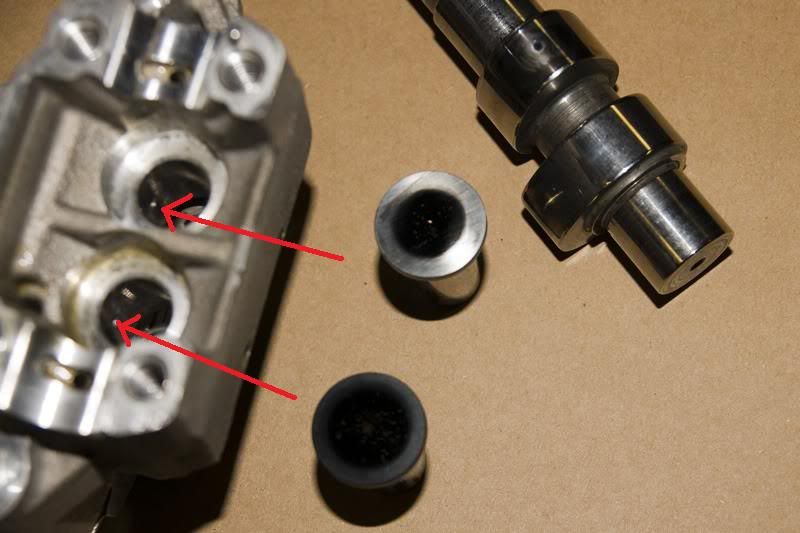

Can't find a thing wrong, everything seems in good condition.

The lash caps on the ends of the adjusters are comprehensively f@cked! and there is irregular wear on the tappet heads. My guess is that for some reason the *upper* tappet in pic #2 has been not turning correctly, looking at it it appears it may not of been radiused properly or the cambox tunnel it runs in has caused it to 'Grab' at some point. That tappet is showing a clearly defined wear ring where the HLD treatment has been degraded and erroded. You'd probably need more accurate measuring equipment than most of us have to check the radius damage but I'll betcha that the noise is due to the uneven nature of the radius due to the wear on the HLD coating.

With damage like that to the lash caps you'll never get an accurate valve lash adjustement which will also contribute to the top end noise.

I'm hoping that the 'I can't see anything wrong' comment was a joke?

Pete

Thinking out loud .....?&%%*pete roper said:But why would a faulty pump only fail to oil one side? It doesn't make sense???

Pete

pete roper said:There is no oil being srayed anywhere Dan, apart from the undersides of the pistons. It's pumped through galleries to the bearing surfaces like water through a plumbing system. Nor are there any 'Perforated bushes'.

Pete

Brian UK said:I can't even attempt to explain anything, the only possibility I could think of was that there may have been a partial blockage on one side, and low oil pressure too. But as we don't know what happened in the oil pump, who can say.

Seems to me there is little point in guessing at what is happening on these few bikes, until someone like Pete has one in his sticky hands to look at properly.