Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Ciao Guest - You’ve landed at the ultimate Guzzi site. NEW FORUM REGISTRATIONS REQUIRE EMAIL ACTIVATION - CHECK YOUR SPAM FOLDER - Use the CONTACT above if you need help. New to the forum? For all new members, we require ONE post in the Introductions section at the bottom, in order to post in most of the other sections. ALWAYS TRY A SEARCH BEFORE STARTING A NEW TOPIC - Most questions you may have, have likely been already answered. DON'T BE A DRIVE-BY POSTER: As a common courtesy, check back in and reply within 24 hours, or your post will be deleted. Note there's decades of heavily experienced Guzzi professionals on this site, all whom happily give endless amounts of their VALUABLE time for free; BE COURTEOUS AND RESPECTFUL!

-

There is ZERO tolerance on personal attacks and ANY HYPERLINKS to PRODUCT(S) or other competing website(s), including personal pages, social media or other Forums. This ALSO INCLUDES ECU DIAGnostic software, questions and mapping. We work very hard to offer commercially supported products and to keep info relevant here. First offense is a note, second is a warning, third time will get you banned from the site. We don't have the time to chase repeat (and ignorant) offenders. This is NOT a social media platform; It's an ad-free, privately funded website, in small help with user donations. Be sure to see the GTM STORE link above; ALL product purchases help support the site, or you can upgrade your Forum profile or DONATE via the link above.

-

Be sure to see the GTM STORE link also above for our 700+ product inventory, including OEM parts and many of our 100% Made-in-SoCal-USA GTM products and engine kits. In SoCal? Click the SERVICE tab above for the best in service, tires, tuning and installation of our products or custom work, and don't miss our GT MotoCycles® (not) art on the BUILDS tab above. WE'RE HERE ONLINE ONLY - NO PHONE CALLS MADE OR RECEIVED - DO NOT EMAIL AND ASK QUESTIONS OR ASK TO CALL YOU.

-

Like the new V100, GuzziTech is full throttle into the future! We're now running on an all-new server and we've updated our Forum software. The visual differences are obvious, but hopefully you'll notice the super-fast speed. If you notice any glitches or have any issues, please post on the Site Support section at the bottom. If you haven't yet, please upgrade your account which is covered in the Site Support section or via the DONATE tab above, which gives you full site access including the DOWNLOADS section. We really appreciate every $ and your support to keep this site ad-free. Create an account, sign in, upgrade your account, and enjoy. See you on the road in 2024.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

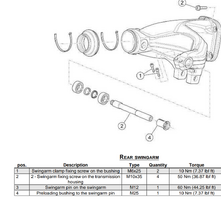

Swingarm bearings.

- Thread starter GTM®

- Start date

I just hit 20,000km so, I’ll add that to the list of things to do / check…

White lithium in my opinion is not a good choice for packing the bearings. My preferred grease is Lucas Red N Tacky. It is rated NLGI GC-LB which is an excellent classification for this application.

I’m with John. White Lithium is a poor choice here.

Every mechanic has their favorites and in my case, I use Lucas Marine grease in applications like this where water intrusion is highly likely. It’s rated identical to Red and Tacky but is many times more water resistant.

I use it on my boat and motorcycles and I assure you, it will never wash out and it’s EP is rated for slower moving bearings whereas the Red is normally for faster spinning bearings.

In truth, either would be 100x better than White Lithium.

Every mechanic has their favorites and in my case, I use Lucas Marine grease in applications like this where water intrusion is highly likely. It’s rated identical to Red and Tacky but is many times more water resistant.

I use it on my boat and motorcycles and I assure you, it will never wash out and it’s EP is rated for slower moving bearings whereas the Red is normally for faster spinning bearings.

In truth, either would be 100x better than White Lithium.

You have to take all the needles out & wash all and same w/pin & outer race to remove the dirt otherwise you are greasing dirt. Just how I do it.

having trouble aligning pin to reattach swingarm. i have a jack in the back on the swingarm but i can’t seem to get the aligned to allow pin to screw in. what am i missing?

i will change to the waterproof grease next season. nobody really mentioned what they are using.

It is easier with the CARC off the swing arm. Then you can maneuver it by hand. Since you don't have the swing arm on yet why not just change the grease now and you won't have to touch it next year.having trouble aligning pin to reattach swingarm. i have a jack in the back on the swingarm but i can’t seem to get the aligned to allow pin to screw in. what am i missing?

yes, I’m thinking about doing that. I’ll pick up some Lucas Marine grease on my way home from work. I do have to swing arm mounted. I have the pin through the first bearing on the shifter side, but I cannot seem to lineup the other side of the swing arm, and thread it in know matter how I move the swingarm. I did pull the pin back enough where I can get my finger in there to try to feel how off-center it is. if i cannot get it. i will unbolt carc

Last edited:

redid the bearings with lucas, unbolted carc, and swingarm pin easily lined up. maybe 1 or 2 alignment shifts at the most. stay tuned…

Attachments

Scott and John, my castle nut has been torqued to spec. now my paint marks are off. did they not torque it properly at factory? or did my sleeve rotate a bit. remember my castle nut/sleeve was hand tight.

Once removed and serviced the paint marks will never line up again. I think the paint marks are like a quality check at the factory that the items were torqued. As I stated earlier, any wear on the bearings will change the positions also every time the "pin" is torqued it will stretch a certain amount. As far as I'm concerned paint marks are useless. Perhaps on a new bike a visual check that something has come loose, but that is about all they are good for.Scott and John, my castle nut has been torqued to spec. now my paint marks are off. did they not torque it properly at factory? or did my sleeve rotate a bit. remember my castle nut/sleeve was hand tight.

100% correct. I can personally attest to this as I witnessed it at the factory.I think the paint marks are like a quality check at the factory that the items were torqued.

metal stretches, and it's a good thing it does, otherwise nothing with threads would ever stay tightScott and John, my castle nut has been torqued to spec. now my paint marks are off. did they not torque it properly at factory? or did my sleeve rotate a bit. remember my castle nut/sleeve was hand tight.

Ditto.100% correct. I can personally attest to this as I witnessed it at the factory.

They indicate a quality check mark.

I'm in the middle of fitting a "new" old Perkins diesel into our old Willard (Long Beach) trawler (that's a boat, in case you are totally motorcycle focused ) It's a drawn out affair. By the end of November I should be ready to tackle the swing-arm bearings on my two carcs. This post has, thanks to all who have posted here, turned into the ultimate tutorial for exactly that. I thank you all

) It's a drawn out affair. By the end of November I should be ready to tackle the swing-arm bearings on my two carcs. This post has, thanks to all who have posted here, turned into the ultimate tutorial for exactly that. I thank you all