Started to go through my 850 T transmission and seeing things that has raised some questions for me.

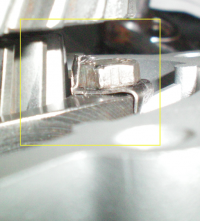

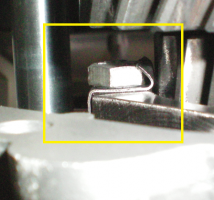

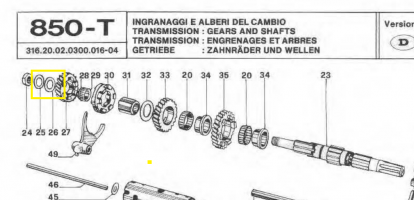

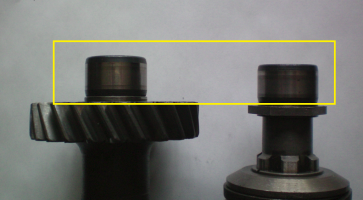

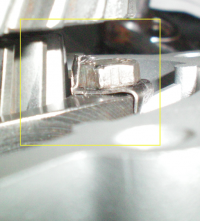

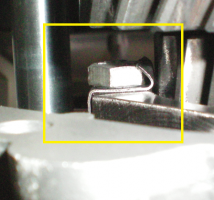

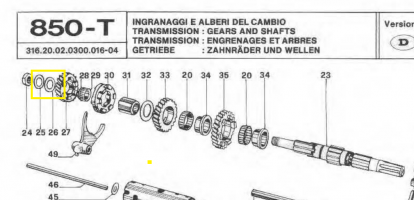

Picture below is my driven shaft as per parts book. My driven shaft has three shims and a washer, the parts book shows one shim and one washer. I'm thinking someone has been into this transmission after it left the factory. Shims outlined in yellow. Should I subtract two shims and go with one as the parts book shows ? Another set of pictures show how close the gear is to the bearing retainer bolt lock tabs on the driven shaft on the transmission cover. Is this normal ?

Picture below is my driven shaft as per parts book. My driven shaft has three shims and a washer, the parts book shows one shim and one washer. I'm thinking someone has been into this transmission after it left the factory. Shims outlined in yellow. Should I subtract two shims and go with one as the parts book shows ? Another set of pictures show how close the gear is to the bearing retainer bolt lock tabs on the driven shaft on the transmission cover. Is this normal ?