buzzer

Tuned and Synch'ed

Hi Guys, thought I would start a thread on my 1100 custom build... I have not started it in earnest just yet, I am currently finishing off a Ducati build, soon as that's finished I will get it on the bike hoist and make a start.

For now, I have just made a couple of parts, some Bell mouths, and a couple of silencers... as I progress I will keep this thread updated. I am not sure on the finished look as yet, but its probably going to be a cafe racer style, but with higher bars as I cant do clip-ons these days!

here is how it arrived...

here is how it looks now, I have acquired a V7 tank for it

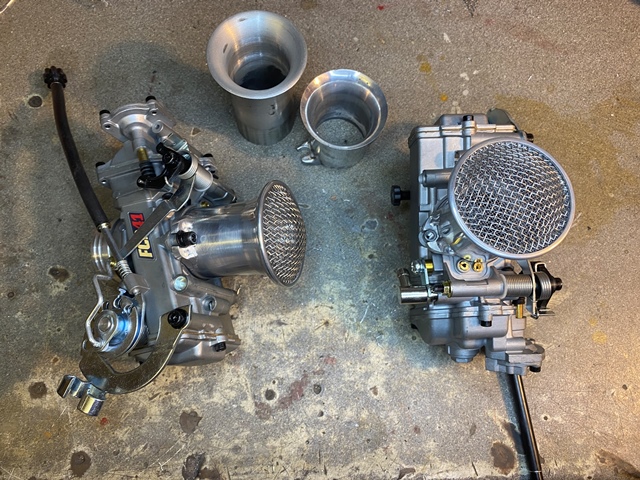

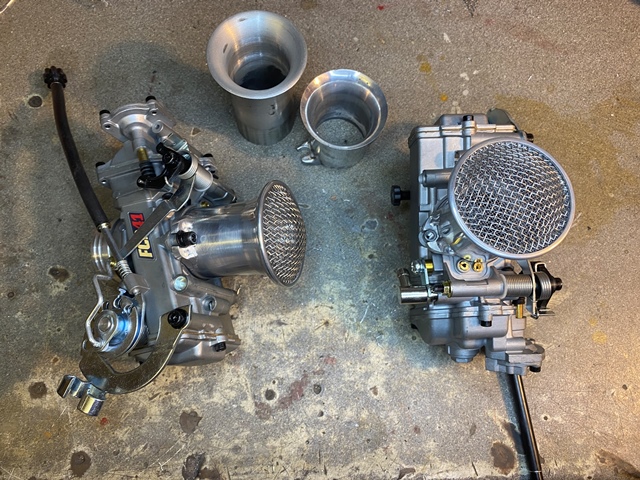

here are the bell mouths I have made, using the metal spinning method

here are the silencers in the fabrication stage

here they are finished

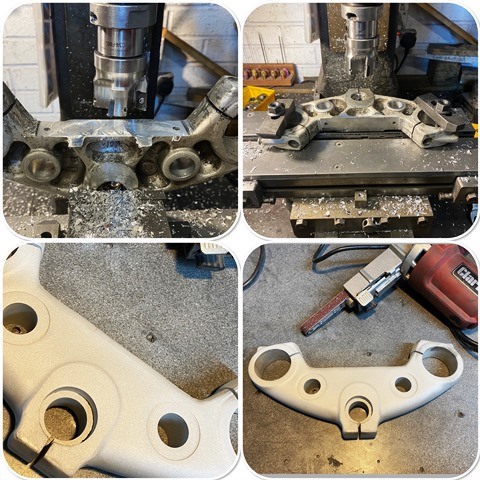

For now, I have just made a couple of parts, some Bell mouths, and a couple of silencers... as I progress I will keep this thread updated. I am not sure on the finished look as yet, but its probably going to be a cafe racer style, but with higher bars as I cant do clip-ons these days!

here is how it arrived...

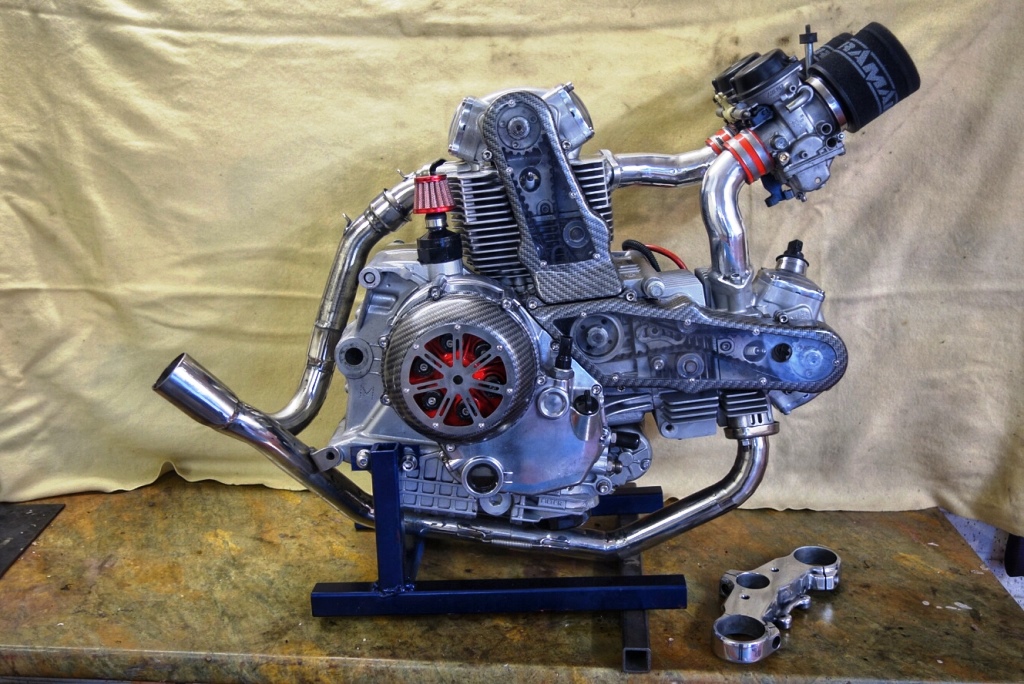

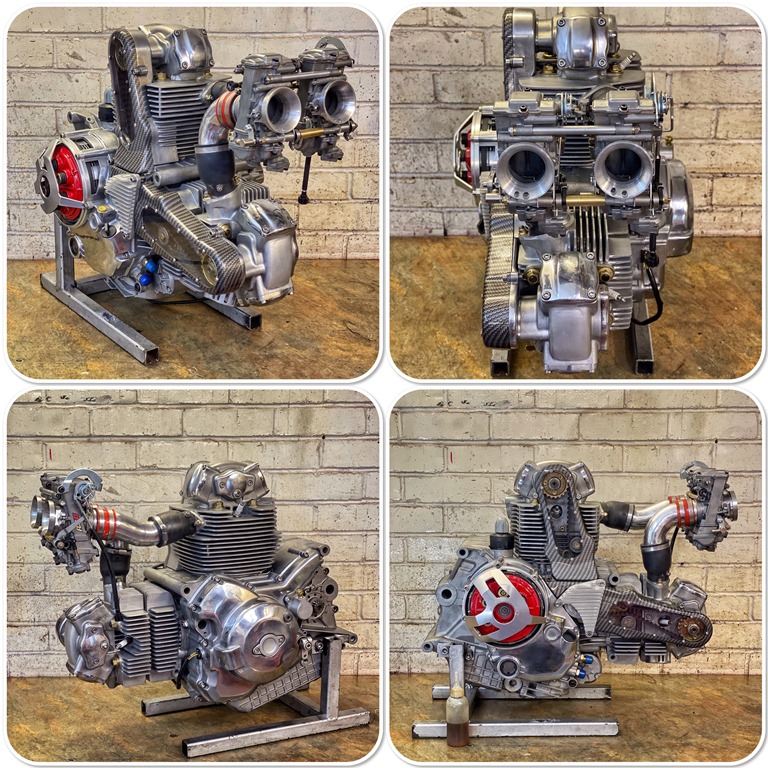

here is how it looks now, I have acquired a V7 tank for it

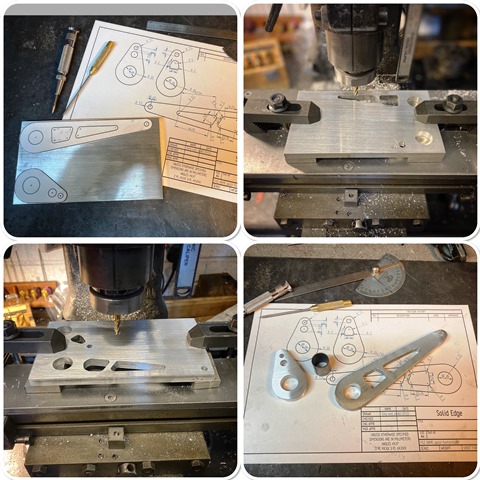

here are the bell mouths I have made, using the metal spinning method

here are the silencers in the fabrication stage

here they are finished