BEFORE WE GET STARTED, IT IS VERY IMPORTANT THAT YOU UNDERSTAND THIS

So, here is the situation:

As a matter of goodwill, Moto Guzzi has previously followed this protocol with regard to repairs to affected motorcycles.

According to Piaggio, motorcycles produced after these specific Serial Numbers / Production Dates, have the implemented design change valve train, and are "roller" engines.

Model - Engine Designation - Last 5 Digits of Serial Number - Date of Production

Stelvio - AC - After AC12596 - 03/12/2012

Griso - A8 - After 13524 - 04/12/2012

Norge - AA - After 12214 - 04/18/2012

What exactly is the problem?

"Flat tappet" refers to the early production 1200 8V engines only. What they are talking about is what type of surface is the contact point between the camshaft lobe and the lifter (a.k.a. a "tappet").

The 1200 8V engine uses a "cam in the head" design to operate the valves. This is a generic camshaft, not the Moto Guzzi one. On it, you can see the round "bearings" which allow the camshaft to spin, and the cam "lobes", the oblong shaped parts that when the camshaft rotates on its axis, that lobe will have a low spot which rotates to a high spot, and then back down to a low spot over and over again:

A general picture of how a camshaft presses a tappet, which moves a pushrod which presses a rocker arm which opens and closes a valve is here. As the camshaft rotates, the lobe presses against the tappet which will move in and out with the shape of the cam lobe. This motion is transmitted through the components to open and close the valves, controlling the movement of gases:

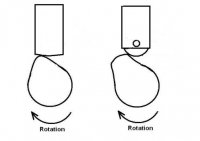

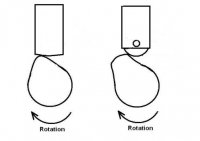

In "flat tappet" engines, the cam lobe rides directly against the face of the tappet. This is the original Moto Guzzi design that has the problem. In "roller" tappet engines, there is a rolling bearing, which rotates around as it presses against the camshaft, thereby the two surfaces glide smoothly against each other. Here is a drawing showing the basic difference:

OK, now that you understand what I am going to talk about here, let's get to the heart of the problem!

In the Moto Guzzi 1200 8V flat tappet engine, the camshaft lobe runs directly on the tappet face itself, which had an anodized black coating put on it called DLC "Diamond Like Carbon" Coating. This coating is an exceptional coating traditionally used on high end components like fork tube suspensions on superbikes like GSXR's etc, because is protects the fork tube sliders and makes for excellent smooth movement of the fork leg. It is also used on internal engine parts including camshafts and even tappets and it is an excellent coating for what it was designed for but as with anything, there are varying degrees of quality and Super High Quality DLC is an expensive process.

However, whomever Moto Guzzi contracted with to make their particular DLC coatings, did a poor job because, in this particular instance within the Moto Guzzi 1200 8V engine, as an internal engine part coating on the flat tappets, which are subjected to the high speed and high heat abrasian of a uncoated yet hardened cam lobe riding directly against it, it quite frankly, sucked. One surface eventually ends up destroying the other.

Here are some examples of DLC coated engine parts (not Moto Guzzi parts):

Moto Guzzi engineers believed that with the proper oil with specific wear resistance additives, their coating would be very durable. Unfortunately. the coatings fail, leaving a hardened cam lobe riding upon a softer steel tappet face, and behold, the tappet faces started to wear!

This is what the solid lifters look like from the top down: (Ed. - GT):

This is what the wear looks like in the Moto Guzzi 1200 8V engine. You can see the coating obliterated from the lower tappet face, and beginning to fail on the upper tappet face, and that same location on the tappet faces, is precisely where the camshaft lobes rides against the tappets:

When this DLC coating failure happens, the valve train will continue to wear and this wear will accelerate as the face becomes more and more beat up and marred, until the point where the cam will start to slowly disintegrate from riding (but literally banging) on this rough beat up surface. It will slowly and steadily get NOISY progressing to very NOISY over time as things are whirring fast in there and surfaces that are not perfect, that collide against each other, become more damaged, and the distance between the two material faces increases, and this increased distance makes a lot of bad banging sounds.

Now...

A roller engine has the flat tappet modified with a rolling bearing face that is now the contact point with the camshafft lobe. This rolling bearing is the same hardness as the camshaft and the DLC coating was deleted. So now, there is no more problem.

Furthermore, oil is forced under pressure into this area and the two surfaces ride against each other with a super fine hydraulic coating of oil between the surfaces and the roller bearing relieves the friction between the two surfaces so there is no appreciable wear on either. Again, problem solved!

This is my personal 2012 Moto Guzzi 1200 8V Stelvio NTX engine with the valve cover removed. It is a factory roller engine. You can see the factory rollers at the top of the engine, inside those two round holes.

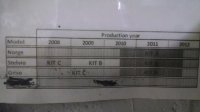

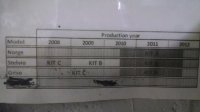

So, For engines like yours, Moto Guzzi has created different "kits" based upon which Engine Designation you have. I provide this table to you as an overview and visual, however, your dealer should check the VIN in the Piaggio database which will give the correct kit:

This is a kit which one of the GuzziTech members purchased while he was in Italy. This is why he also has the cool logos and stickers!

If I remember correctly, he was going to "rollerize" his engine even though he had experienced no failure yet. So, he was proactively doing this conversion, and Moto Guzzi will not pay for proactive repairs:

Still with me? Good. Almost done.

So, based upon your VIN number, and your audio tape, I believe but cannot be absolutely certain, that your engine is experiencing this DLC / flat tappet failure and that the sound you are hearing is an indication of this. If I am correct, the sound will only get louder over time.

Unfortunately, you cannot actually see the tappet faces (like in the earlier photo above) unless the camshaft box assembly is removed. You will need a mechanic for this. The good news is that if you have perfect service records, then you will be fixed for free, of this I am certain. Otherwise, you will have to pay the labor to repair it which still, isn't a bad deal from Moto Guzzi.

The 1200 8V engine is an awesome engine but it is picky and I recommend that you always use the factory recommended oil which you can get online. Just Google "Eni 4T 10W-60"

I know this was a lot to read and digest, but I have shared with you everything you need to know to make an informed decision about this. Please get your bike to your mechanic ASAP and have it checked and hopefully repaired.

If you have another question Paul, let me know.

Best wishes!

Scott

UPDATED 10/12/2020

I am attaching 2 TSB (Technical Service Bulletins) - merged into 1 PDF file - regarding Moto Guzzi's Official Position on this issue.

PLEASE READ THEM COMPLETELY BEFORE JUST SHOOTING OFF QUESTIONS! IT ANSWERS EVERYTHING ABOUT THEIR POSITION, WHICH KIT TO USE, ETC. THANKS! - Scott

Nobody can perfectly diagnose a motorcycle issue fully and competently via a description and a sound clip over the internet. Experienced individuals may be able to narrow the issue down, and even have a strong opinion about what the problem is, but there is no substitute for actually being able to touch, and listen to a motorcycle which is right in front of you.

Having clarified this point, in my opinion, based upon very limited information, this issue which I am about to explain, may be your problem.

I am not saying that your motorcycle has this problem but rather, that I believe it is a prime candidate for this issue, and that the best and final definitive diagnosis will have to come from your local Moto Guzzi certified mechanic.

So, here is the situation:

- The valvetrain (valves and associated components) is basically the part of the motor which controls the movement of the air and fuel mixture "charge" during intake, to be allowed into the cylinder, trapping it there during the compression phase, and the power stroke, and then during the exhaust phase, allowing the burnt hot waste gases out of the cylinder to be passed into the exhaust pipes to be expelled out into the atmosphere.

- All of the Moto Guzzi 1200 8V engines manufactured prior to mid year production in 2012, have a potential serious issue with the valvetrain.

- This problem is due to an engineering design flaw in the choice of materials used in the construction of the valve train on all of these affected engines.

- This design flaw was not known until after the motorcycles were already sold and into the hands of customers. It took time for it to begin to appear on different motorcycles.

- Not every Moto Guzzi 1200 8V engine has exhibited this problem yet. Some motorcycles have many miles on them without any issue, while others have relatively low mileage and have developed the issue. Because this is not a universal guaranteed failure, and no injuries have occurred due to it, there is no formal recall by Moto Guzzi for this particular problem. However, it is the concerted opinion of the majority of competent mechanics and many educated owners, that failure is only a matter of time; that in essence, the affected valve train is a proverbial "ticking time bomb". I happen to be one of the people who is convinced of this problem and its eventual manifestation in all affected Moto Guzzi 1200 8V engines at some point in time.

- Since this issue was discovered by customers, dealers and mechanics and subsequently reported to Moto Guzzi, the company, without admitting any wrong-doing, changed the way the valve train is constructed.

As a matter of goodwill, Moto Guzzi has previously followed this protocol with regard to repairs to affected motorcycles.

Motorcycles which have a dealer confirmed problem, and for which the customer can demonstrate a complete service history being performed solely at authorized dealers, have received free of charge, both the parts and labor to convert the affected engines to effectively the same design as the new designed engines.

Motorcycles which have a dealer confirmed problem, but for which the customers cannot demonstrate a complete dealer service history being performed, have been provided the conversion kit parts free of charge, and have had to either pay for a mechanic to install the parts, or if they are highly skilled, they have installed them by themselves.

Motorcycles which have exhibited no problem, have received nothing as Moto Guzzi's official position is "if there is no problem, then there is no problem".

Moto Guzzi believes that use of any oil in the 1200 V8 engine, other than the factory specified oil, has been the proximate cause of any and all valvetrain damage, and this is why they will only pay the entire repair bill if a dealer has performed all services and this can be verified.

Now, so you will understand the nomenclature used here:- All 1200 8V engines manufactured before the implemented design change, are called "flat tappet" engines while all 1200 8V engines manufactured after the implemented design change, are called "roller" engines. This term relates to the type of valvetrain that the particular engine has in it which I will explain in a moment.

- Furthermore, engines with the implemented design change come in two varieties, "rollerized" engines (an engine which has been updated with the kit to repair the defective design), and "factory roller" engines (indicating an engine which was produced at the Moto Guzzi factory after the implemented design change).

- As you might expect, "factory roller" engines have no problem at all.

According to Piaggio, motorcycles produced after these specific Serial Numbers / Production Dates, have the implemented design change valve train, and are "roller" engines.

Model - Engine Designation - Last 5 Digits of Serial Number - Date of Production

Stelvio - AC - After AC12596 - 03/12/2012

Griso - A8 - After 13524 - 04/12/2012

Norge - AA - After 12214 - 04/18/2012

What exactly is the problem?

"Flat tappet" refers to the early production 1200 8V engines only. What they are talking about is what type of surface is the contact point between the camshaft lobe and the lifter (a.k.a. a "tappet").

The 1200 8V engine uses a "cam in the head" design to operate the valves. This is a generic camshaft, not the Moto Guzzi one. On it, you can see the round "bearings" which allow the camshaft to spin, and the cam "lobes", the oblong shaped parts that when the camshaft rotates on its axis, that lobe will have a low spot which rotates to a high spot, and then back down to a low spot over and over again:

A general picture of how a camshaft presses a tappet, which moves a pushrod which presses a rocker arm which opens and closes a valve is here. As the camshaft rotates, the lobe presses against the tappet which will move in and out with the shape of the cam lobe. This motion is transmitted through the components to open and close the valves, controlling the movement of gases:

In "flat tappet" engines, the cam lobe rides directly against the face of the tappet. This is the original Moto Guzzi design that has the problem. In "roller" tappet engines, there is a rolling bearing, which rotates around as it presses against the camshaft, thereby the two surfaces glide smoothly against each other. Here is a drawing showing the basic difference:

OK, now that you understand what I am going to talk about here, let's get to the heart of the problem!

In the Moto Guzzi 1200 8V flat tappet engine, the camshaft lobe runs directly on the tappet face itself, which had an anodized black coating put on it called DLC "Diamond Like Carbon" Coating. This coating is an exceptional coating traditionally used on high end components like fork tube suspensions on superbikes like GSXR's etc, because is protects the fork tube sliders and makes for excellent smooth movement of the fork leg. It is also used on internal engine parts including camshafts and even tappets and it is an excellent coating for what it was designed for but as with anything, there are varying degrees of quality and Super High Quality DLC is an expensive process.

However, whomever Moto Guzzi contracted with to make their particular DLC coatings, did a poor job because, in this particular instance within the Moto Guzzi 1200 8V engine, as an internal engine part coating on the flat tappets, which are subjected to the high speed and high heat abrasian of a uncoated yet hardened cam lobe riding directly against it, it quite frankly, sucked. One surface eventually ends up destroying the other.

Here are some examples of DLC coated engine parts (not Moto Guzzi parts):

Moto Guzzi engineers believed that with the proper oil with specific wear resistance additives, their coating would be very durable. Unfortunately. the coatings fail, leaving a hardened cam lobe riding upon a softer steel tappet face, and behold, the tappet faces started to wear!

This is what the solid lifters look like from the top down: (Ed. - GT):

This is what the wear looks like in the Moto Guzzi 1200 8V engine. You can see the coating obliterated from the lower tappet face, and beginning to fail on the upper tappet face, and that same location on the tappet faces, is precisely where the camshaft lobes rides against the tappets:

When this DLC coating failure happens, the valve train will continue to wear and this wear will accelerate as the face becomes more and more beat up and marred, until the point where the cam will start to slowly disintegrate from riding (but literally banging) on this rough beat up surface. It will slowly and steadily get NOISY progressing to very NOISY over time as things are whirring fast in there and surfaces that are not perfect, that collide against each other, become more damaged, and the distance between the two material faces increases, and this increased distance makes a lot of bad banging sounds.

Now...

A roller engine has the flat tappet modified with a rolling bearing face that is now the contact point with the camshafft lobe. This rolling bearing is the same hardness as the camshaft and the DLC coating was deleted. So now, there is no more problem.

Furthermore, oil is forced under pressure into this area and the two surfaces ride against each other with a super fine hydraulic coating of oil between the surfaces and the roller bearing relieves the friction between the two surfaces so there is no appreciable wear on either. Again, problem solved!

This is my personal 2012 Moto Guzzi 1200 8V Stelvio NTX engine with the valve cover removed. It is a factory roller engine. You can see the factory rollers at the top of the engine, inside those two round holes.

So, For engines like yours, Moto Guzzi has created different "kits" based upon which Engine Designation you have. I provide this table to you as an overview and visual, however, your dealer should check the VIN in the Piaggio database which will give the correct kit:

This is a kit which one of the GuzziTech members purchased while he was in Italy. This is why he also has the cool logos and stickers!

If I remember correctly, he was going to "rollerize" his engine even though he had experienced no failure yet. So, he was proactively doing this conversion, and Moto Guzzi will not pay for proactive repairs:

Still with me? Good. Almost done.

So, based upon your VIN number, and your audio tape, I believe but cannot be absolutely certain, that your engine is experiencing this DLC / flat tappet failure and that the sound you are hearing is an indication of this. If I am correct, the sound will only get louder over time.

Unfortunately, you cannot actually see the tappet faces (like in the earlier photo above) unless the camshaft box assembly is removed. You will need a mechanic for this. The good news is that if you have perfect service records, then you will be fixed for free, of this I am certain. Otherwise, you will have to pay the labor to repair it which still, isn't a bad deal from Moto Guzzi.

The 1200 8V engine is an awesome engine but it is picky and I recommend that you always use the factory recommended oil which you can get online. Just Google "Eni 4T 10W-60"

I know this was a lot to read and digest, but I have shared with you everything you need to know to make an informed decision about this. Please get your bike to your mechanic ASAP and have it checked and hopefully repaired.

If you have another question Paul, let me know.

Best wishes!

Scott

UPDATED 10/12/2020

I am attaching 2 TSB (Technical Service Bulletins) - merged into 1 PDF file - regarding Moto Guzzi's Official Position on this issue.

PLEASE READ THEM COMPLETELY BEFORE JUST SHOOTING OFF QUESTIONS! IT ANSWERS EVERYTHING ABOUT THEIR POSITION, WHICH KIT TO USE, ETC. THANKS! - Scott

Attachments

Last edited: