There are many roads to Rome, right?

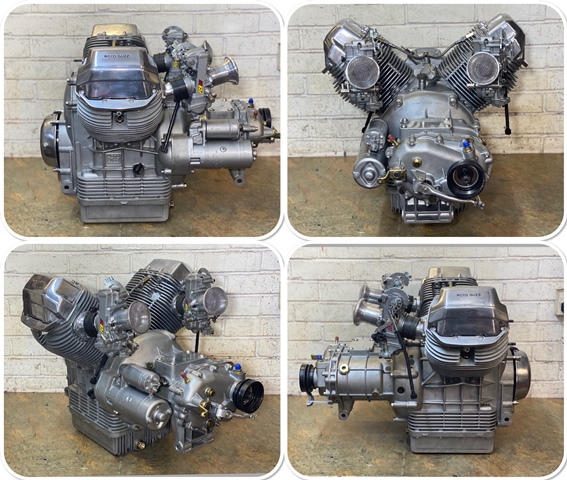

I have 2 cabinets in my workshop. One glass bead as well and the other dry soda.

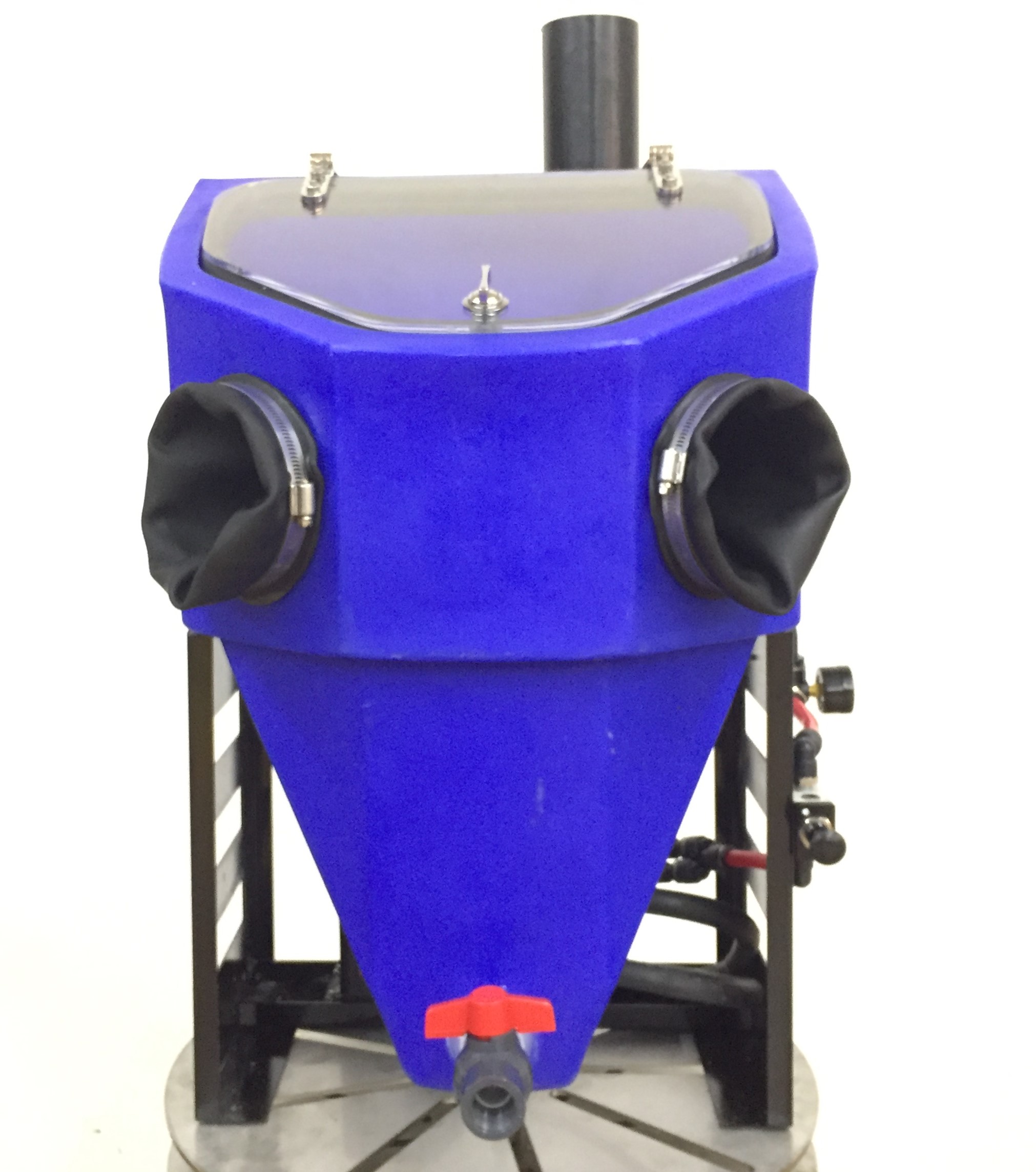

I really am looking forward to a vapour blasting cabinet next year though.

I have 2 cabinets in my workshop. One glass bead as well and the other dry soda.

I really am looking forward to a vapour blasting cabinet next year though.